Tecnologia metalla processantur electricas control cabinetis est procedus metalla utilizationis ad succidendum, bending, welding, assembly et ceteris procedentibus ut materiales metallos in formam et granditudinem desiderantur. Hodie discamus de utilitates technologiae processionis metallorum electricae electricae control cabinetis cum artificio metallorum processionis editor?

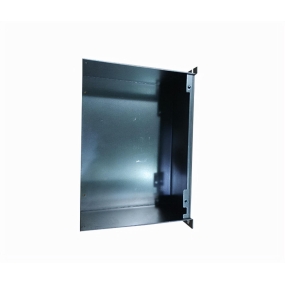

The Sheet Metal Processing technology for electrical control cabinets plays a very important role in the production of electrical equipment, and its advantages are mainly reflected in the following aspects:

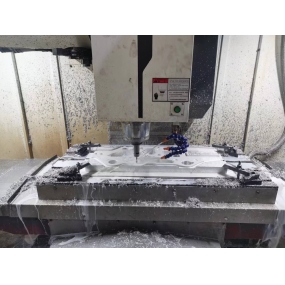

1 , High precision: The sheet metal processing technology of the electric control cabinet uses CNC equipment for processing, which has high precision and can ensure that the size, shape, and quality of the product meet the requirements, ensuring the stability and reliability of the product.

2 , High production efficiency: The sheet metal processing technology of the electric control cabinet adopts an automated production line, which has high production efficiency, can greatly improve production efficiency, shorter production cycle, and save labor and time costs.

3 , Good processing quality: The sheet metal processing technology of the electric control cabinet adopts advanced equipment and technology, which can ensure the processing quality of the product, avoid quality problems caused by manual operation errors and unstable factors, and ensure stable product quality.

4 , Customized production: The sheet metal processing technology of the electrical control cabinet can be customized according to the specific needs of customers, and personalized design and processing can be carried out according to customer requirements to meet their various needs.

5, - Energy saving and environmental protection: The sheet metal processing technology of the electric control cabinet adopts advanced processing equipment and processes, which can reduce energy consumption and waste rate, achieve energy-saving and environmentally friendly production, and meet the requirements of sustainable development of modern industries.

6 , Low cost: The sheet metal processing technology of the electric control cabinet adopts automated production lines and CNC equipment, which can reduce production costs, improve production efficiency, thereby reducing product production costs and enhancing the competitiveness of the enterprise.

In summary, the sheet metal processing technology for electrical control cabinets has the advantages of high precision, high production efficiency, good processing quality, customized production, energy conservation and environmental protection, and low cost. It is of great significance for the production and manufacturing of electrical equipment, which can improve product quality and production efficiency, reduce costs, and provide strong support for the development and growth of enterprises.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole