In multi station progressive continuous stamping die, precision stamping parts processing plant stamps the work piece of the nail arranging machine, completing the processes of rolling forming and welding. However, there is still a small part that is connected to the stamped sheet metal, and the stamped and welded work piece is carried by the stamped sheet metal into the ultrasonic surface treatment equipment for removal of rust proof grease and welding slag. Complete the removal of welding beads and burns in the shooting room.

Hoc est essential ut non efficiat circulos breves et electricas breves in utilizacione partium precision is stampionis. In secundo brevissimo tratione ultrasonicae superficie, antequam inspectionem qualitatis partium pulsavorum, ultrasonica superficie finientem technologiam iterum utilizat ut reliquias reliquas auferat per manipulationem pulsavi. Post completionem omnium operibus supra, partibus pretiosis partibus absque folio vacuum separati sunt et separati sunt. Puncti partibus cum pauca qualitate machinae ad arrangindum clavos in rubiculo positi sunt, dum qualificatae partibus pulseris directo ad atrium phagamentorum mittantur.

In the process of producing precision stamping parts, damage may occur due to factors such as the service life of hardware molds, mold structure planning, selection of mold steel, heat treatment, surface treatment, mechanical processing and grinding, wire cutting technology, stamping equipment and processes, mold smoothness, maintenance and repair level, etc. Quomodo evadere damnationem precision stamped partes in manu mille @ @ 000? Sequentes tres sunt ad referendum nostrum:

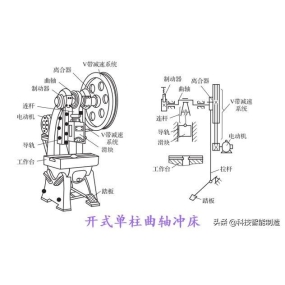

1. Revamp stamping equipment to improve production safety and reliability. Multae elementi insecuri sunt in systema operationis et electrica controlo multorum praepositorum pulseris nunc nunc. Si continuantur utili, meliora tecnica correspondent. Stamping equipment manufacturers should improve product design to ensure the safety and reliability of stamping equipment.

2. Equipment protection devices. Pro parvo volumine production is, oportet arma defensionis securitatem in operibus stampionis, quae non potest automaticamentur aut utilizat instrumenta stampionis securitatis ut non evaderet accidentes perditionis causae errorum operationis. Various protective devices have their own characteristics and application scope, and incorrect use can still result in injuries accidents. Accordo, necesse est explicare rola diversorum instrumentorum protectionis ut corrigentem utilitatem et operationem securam esset.

3. Transforme processes, molds, and operating methods to complete manual mold work. For large scale production operations, mechanization and automation can be achieved by changing processes and molds. For example, choosing automated, multi station stamping machinery equipment, using multi cutting tools and mechanized production equipment, and using combined process methods such as continuous molds and composite molds. Omnes non solum praecipient salutem pulserum operationum, sed etiam multo meliora productionem potentiam.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque