Electric spindle is a new technology that has emerged in the field of CNC Machining in recent years, integrating machine tools spindle and spindle motor. Along with linear motor technology and high-speed tool technology, it will push high-speed machining into a new era. The CNC machining spindle is a set of components, which includes the electric spindle itself and its accessories: electric spindle, high-frequency converter, oil mist lubricator, cooling device, built-in encoder, and tool changer.

High speed spindle is the most important key technology in high speed cutting technology and also the most important component of high speed cutting machines tools. High dynamic balance, good rigidity, high rotational accuracy, good thermal stability, sufficient torque and power transmission, high centrifugal force tolerance, accurate temperature measurement device and efficient cooling device are required. Velocitate velocitatis alta generale facit velocitatem spindle non minus quam 40000 r/min et potentiam spindle maior quam 15 kW. Usually, electric spindle components with integrated spindle motors are used to achieve direct transmission without intermediate links. Induction integrated spindle motors are mostly used for motors. Currently, hot pressed silicon nitride (Si3N4) ceramic bearings, liquid dynamic and static pressure bearings, and air bearings are commonly used. Lubrication often uses techniques such as oil air lubrication and jet lubrication. Aurigendum spindle generale per aquam interiorem frigidum aut aerum frigidum spindle conplebitur.

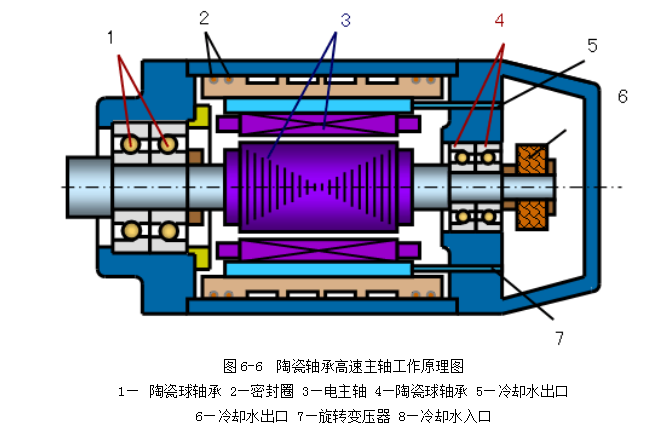

1. Working principle diagram of ceramic bearing high-speed spindle

Diagramma supra monstrat principem operantis ceramici portantis spindle alta velocitatis, C aut B gradus precision angularum portantium ballarum contactorum. Arrangementum portantis similis est tradicioni structurae grinder spindle. Adopting a "small bead dense ball" structure, the ball material is Si3N4; Adopting electric spindle (motor and spindle integrated); Valor caracteristicis velocitatis portantis (=? Diametrus scaft (mm), velocitas (r/min)) a 1.2 ° C in comparatione cum portantibus fertilibus ordinaris Twice, 0,5-1106 attingere potest. Exalta precisa rotationis cum errore rotationis minus quam 0,2 μm fluctibus portantibus hydrostaticis et minus quam 0,05 μm in portantibus hydrostaticis aeris; Low power loss; Velocitat velocitatis portantium hydrostaticam liquidorum 1106 attingere potest, et velocitas proprietatis portantium hydrostaticam aeris 3106 attingere potest. The load-bearing capacity of air static pressure bearings is relatively small.

Comparata est cum ballis fertilibus fertilibus ceramicam

(1) Densitatio ballarum ceramicam a 60% reducitur, quæ potentiam centrifugalam magnam dimittere potest.

(2) The elastic modulus of ceramics is 50% higher than that of steel, which gives bearings higher strength;

(3) Ceramicam humilior coefficient friccionis habet, qui calefactum portantem, portantem et perditionem potentiae reddere potest.

(4) Ceramikalar resistans ve uzun hayat taşıyan iyi giysiler.

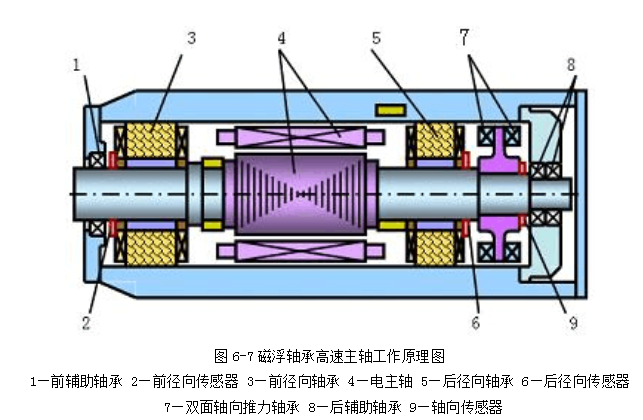

2. Maglev portans velocitatem spindle

Diagramma supra monstrat principem operantis spindali altissimi velocitatis cum portantibus levitation is magnitudinis. spindalum duobus portantibus levitationis radialis et duobus magnitudinis axialis suportatur, et gapus inter statorem et rotorem portantium magnitudinis est circa 0.1mm. excelsa stirpe decem vicibus stirpe pilae portantis spinam Valor characteristica velocitatis rotationis 4106 attingere potest? The rotation precision mainly depends on the accuracy and sensitivity of the sensor, as well as the performance of the control circuit, and can currently reach 0.2 μ m. Struktura mechanica et circuit systema utraque relative complexa sunt; propter generationem caloris excelsam est requis ad faciendum systemae frigidae

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque