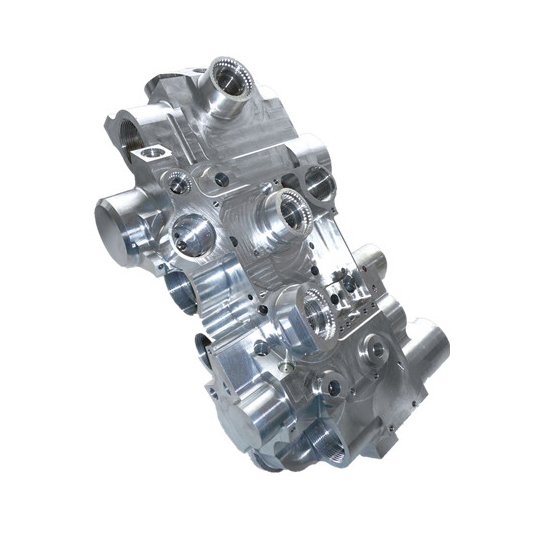

Numerical control quinque axis machinatura est machinatura optima et precisa tecnologia amplius utilisa in aviatione, aerospace, automotiva, molda et aliis regionibus. Principulus functionis machinationis quinque axis CNC explicito summarizabitur sicut: 1. Sistema basica coordinatationis in machinatione CNC quinque axis, secundum regulas ISO, system a coordinatationis dextrae Cartesiae utilitur ad descriptionem motion instrumenti machinae CNC. Inter eos axis coordinatus paralelatus ad axim principem definitur quasi axis Z, et coordinatus rotation is circum Axes X, Y et Z sunt A, B et C respectively. Mobilitate singulae axis coordinatae (X, Y, Z, A, B, C) a movemento tabulae aut instrumenti operationis potest attingere, sed directo a oriente relativa motion is instrumenti ad operam partem definita est. Usually, five axis link refers to linear interpolation motion of any five coordinates in X, Y, Z, A, B and C. Alios sermones, quinque machina axis combinabitur tres axis moventium (X, Y, Z) et omnes duas axes rotantes (sicut Axes A et C). 3, 2. Instrumento controlo et positio: The spindle of a CNC five axis tool can control the rotation of the tool. By accurate positioning and controlling the spindle speed, different positions of the workpiece can be machined. Coordinate system control potest tres dimensionalis moveri instrumenti in labor partibus per X, Y et Z asses controllare. Assis X controlat movendum instrumenti in oriente horizontale, Assis Y controlat movendum instrumenti in oriente perpendiculare ad axis X, et Axis Z controlat movendum instrumenti in oriente perpendiculare ad avionem XY Asses rotationis (sicut Asses A et C) potest instrumentum in diversis angulis rotare, id est machina superficium complexorum in operibus. Assis A usus rotationem instrumenti in circuitu axis X controlat, cum Axis C rotationem instrumenti in circuitu axis Z controlat The machining path planning CNC system control s the movement of each axis's stepper motor or servo motor through a computer based on a pre-programmed machining program, thereby achieving control over the machining of the workpiece. Haec computatio precisa et planatio viae instrumentorum includet, assecurantia ut instrumentum secundum viam predeterminatum machinari potest. 4 , ut accuracionem et qualitatem machinarum asseguratur, CNC quinque instrumenta machinarum ad mensuram magnam precisionem utilizata sunt, qui possunt positionem et magnitudinem operantis in tempus reale observare. Through feedback from the measurement system, the CNC system can make corresponding adjustments to ensure the accuracy of machining.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque