Sex procedurae sunt in productione semiconductorum cabinetorum, quae basically sunt: product design&mdash& mdash; Cutting and cutting materials&dash& mdash; Puncti procedentibus&Dash&e mdash; Bending processing&dash& mdash; Welding continuity&dash& mdash; Ut alta qualitate semiconductor cabinetis producere, necessitates per singulos gradus valde strictae sunt in aspectu tratione. 1 , The mission of semiconductor cabinet product design is to conduct experimental discussions on the product structure concept, constituent components, and related new principles, processes, etc. of new products to obtain the required parameters for design, draw a sketch of the semiconductor cabinet, confirm the detailed architecture, dimensions, and technical conditions of each component of the new product, calculate the layout and strength and rigidity of the whole machine, conduct technical analysis of the semiconductor cabinet product, and verify whether its function and cost meet the requirements of the product development plan.

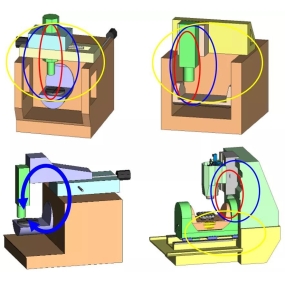

Prima procedura semiconductor cabinet production& mdash; In principio, multi fabricatores semiconductoris cabinetis basebantur in dimensionibus in drawingibus designationis produktorum, et tunc plateas calicatas ad aplicationem online emit. Salvatores non solum in una procedura, sed etiam in consummatione, investimento equipmentorum, et investimentum hominis in manu productionis. EMAR Technology Co., Ltd. was established in August 2016. Its original address was Xinpo Duyuan, Changbu Village, Xinyu Town, Huiyang District, EMAR City, Guangdong Province. Its current address is Building B17, Queshuiyang Slope Factory, Huiyang District, EMAR City, Guangdong Province. Since its establishment, the company has mainly engaged in sheet metal structure design and production supporting processing We are committed to the production and manufacturing of supporting products in the fields of semiconductor equipment, stainless steel equipment (including specialized production lines for mirror stainless steel processing), financial equipment, medical equipment, network applications, and more. The company's existing equipment mainly includes CNC punching machines, lasers, CNC folding machines, gantry milling machines, robotic welding, spraying lines, screen printing lines, and electronic assembly lines. At the same time, the company has improved its strict quality management system and passed the ISO9001:2015 quality system certification. The advanced supporting equipment and strict quality management system enable the company to meet the various needs of customers in terms of contracting, delivery time, and quality. 3, " Stamping and stamping production of semiconductor cabinets is the process of processing metal materials using stamping equipment and molds. 4 , The bending process of semiconductor cabinet workpieces is carried out on machine presses, friction presses, or hydraulic presses. In addition, it is also carried out on specialized equipment such as bending machines, pipe bending machines, and stretch bending machines. Characteristica pulsationis est quod objectus in line a recta movetur, quod dicitur bending; Objekti in decoratione quidam instrumentorum specializatorum incurvatio et converso dicitur bending aut hydraulic. 5,Procedus fermenti semiconductoris cabinetis purus esse et etiam sine defectus, sicut fractura, subcuta, notches, et ardere. Defectiones quales porti, trabes, inclusiones, trabes, etc. non oportet esse in superficie et non apparere intrinsecus. firma et robusta erit funiculus et solvator super faciem componentium repletur in loco sine fragmentis 6 , Processus semiconductorum cabinetorum superficie tractionis humiliationem et reticulum involvet, secundum phosphationem ut formaret layer protectiva phosphatis ad blocare aerum et prohibere oxidationem superficie semiconductor is cabinetis. Tad, pulverum coationem applicatur pro robustum coationem super superficiem semiconductoris cabinetis formatur.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque