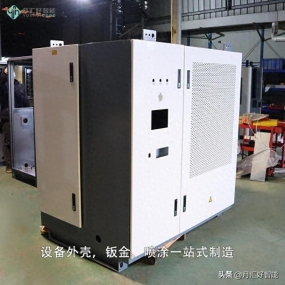

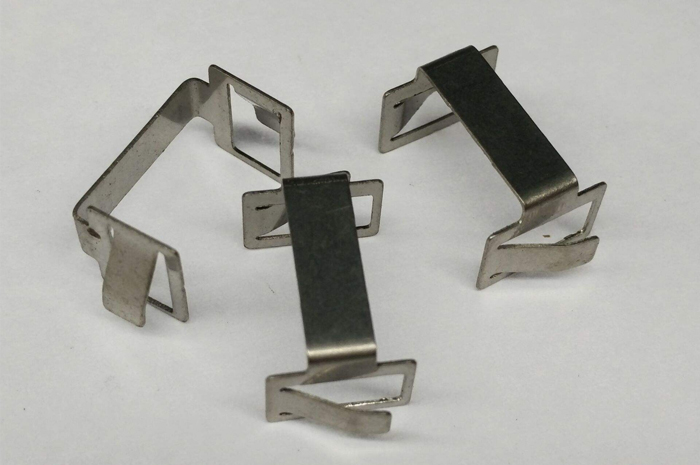

What are the classifications of Metal Stamping molds? EMAR Precision will give you a brief introduction. For metal stamping molds, we can simply divide them in three types: engineering molds, conformity molds, and continuous molds. These are several commonly used molds in metal stamping factories. Below, we will briefly introduce these three types of molds:

Partibus metallis

Ingenia mold a: Haec typus stampionis metallorum manum aut roboticam opus necessit ut auferat produktum de molda et ponet illum in sequente molda ut continuat produktio usque ad unum processum molae finitur, et totum produktum consiliatur completum. Maintenatio est relativamente simpla, sed fabricatio est tempus consummatio et labor-intensa, multa opus et temporis pretio requirant, et produktio pulchritudo alta est.

Compositi mola: Hic tipus metal stamping mola habet alteram structuram ab alteris mola ingeniae. Its punch is designed in lower mola, et alteri templi sunt lower clamping plate (fixed convex mola), lower blocking plate, et lower stripping plate (stripping) in sequence. The upper mol compositus est de mater mola (or cutting edge), intrintra stripping plate, et supera backing plate in sequence. The stripping is suspenditus in summitate lapis similis similis altitudinis, et tunc subtitus est per virum aut spring. For in qua est.Exemplo, in mola composita pro puncti utilizata est, interiora strippa est generale 0,50mm a mola matris et non potest inferior quam mola matris, alioquin angulum molae matris pronus ad chipingam aut non potest separare.

Partibus metallis

Continuous mold: This type of metal stamping mold is difficult to maintain and requires experienced assembly workers to operate, but it has high production efficiency. If the punching is fast, thousands of metal stamping products can be produced in one hour, saving labor and time costs, and the product scrap rate is low.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque