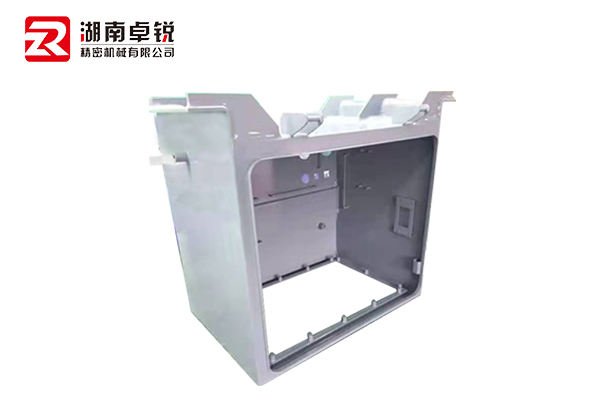

Quid sunt gradus metallis processationis chassis et cabinetis? Hodie discamus simul cum artificio fabricatore metallico.

Exeuntia lapides metallis processionis in cassis cabinetis prima sunt sequentes stages:

1. Design and Planning: First, engineers will develop a design plan for the chassis and cabinet based on the customer's needs and requirements, and determine the required materials and processes. Designers use computer-aided design software to create 3D models of products in order to better understand their structure and dimensions. "

2. Material preparation and cutting: Prepare the required metal sheet according to the design plan, and use cutting machinery to cut the sheet according to the design drawings to ensure that the metal sheet is cut into the required size and shape. "

3. Bending and Forming: Use bending machinery to bend metal sheets in shapes that meet design requirements. Haec gradus opus facientes praecipientes praecipientes operabilitates et praecipientes potestates mensurae habere. "

Welding and assembly: Use welding equipment to weld various components to form the basic structure of the chassis cabinet. Postquam ferebatur, congregate et installate alias accessories, quales claves ostium, radiatores etc. "

4. Medicina superficie et inspectione qualitatis: tractura superficie chassis et cabinetis, sicut spraying, polishing, etc., ut cresceret qualitatem apparentiae et durabilitatem produkti. Simultaneously conduct quality inspection to check whether the product meets the design requirements and standards. "

In addition, the detailed process of chassis Sheet Metal Processing also includes steps 2 such as cutting, bending, punching, welding, surface treatment, assembly and testing. The processing steps for sheet metal chassis cabinets are more detailed, including design and planning, material selection, cutting, forming, welding and connection, precision machining, surface treatment, quality control, assembly, inspection and testing, packaging and delivery, etc. These steps together constitute the complete process of chassis and cabinet sheet metal processing, ensuring that the quality and performance of ZUI final products meet the requirements. "

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque