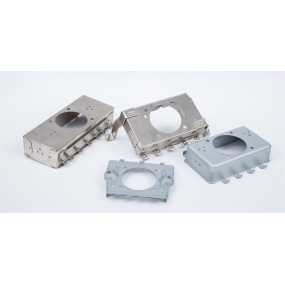

Sheet metal shell processing is a common metal processing technique, suitable for producing shells and casings of various mechanical equipment. Procedus processionis in sequentibus septem gradibus divisus est:

1. Design plan: Before carrying out sheet metal shell processing, it is necessary to design a suitable plan. Based on the requirements and functions of the product, determine the design parameters such as shape, size, and structure of the shell, and draw detailed engineering drawings.

2. Material preparation: Select suitable metal materials as raw materials for sheet metal shells. Materiales communes includent lapidem frigidum, lapidem calidum rollatum, steelam sterilis, etc. Cut et trim materiales secundum propositiones, et parate eas in granditudinem et formam.

3. Programmatio: Perform numerical control programming according to the design drawings and requirements. Per programmandum viam machinae instrumenti, sequentia et parametros sectionis, bending, stamping et alias operationes determinantur parare ad subsequentes machinas.

4. Cutting: Use CNC cutting machines to accurately cut prepared metal materials. Secundo programmam constituentem, exercite opera succidere materiam in voluntatem formam et granditudinem.

5. Bending: Bending the cut metal sheet to shape it in the desired shell shape. Usate CNC bending machine to bend metal plates, ensuring that the structure and dimensions of the shell meet the design requirements.

6. Stamping: Using CNC punching machines for stamping processing, punching, cutting and other operations on the shell. According to the design requirements and program settings, carry out stamping operations to ensure that the shell has the required functions and assembly hole positions.

7. Welding and assembly: Welding, splicing, and assembling the processed sheet metal shell. congregate diversos componentes, conputate illos simul, assecurate structuram calices firmam et bene signatum, et facite faciem facientem, ut faciat illum splendorem et flatum.

Superior est procedus operation is generalis fabricationis metallorum fabricationis. Per processione precisa et congregatione, varia fabrica shell quae meet design requirements can be produced to meet the various functions and needs of mechanical equipment.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque