Hodie, breve loquamur super quomodo fabricos pulsere hardware protegamus et reparamus plateam discharge in mollis pulsere:

1. Desolabilitate plateae desolationis in fuscino metallo potest balansere et levare primo cum duobus torrentibus, et tunc balansere utraque manibus ut auferat fortitudinem. Cum adversus difficultates in disassemibilitate, necesse est verificare si intrinsecus fuscini mundus est, si omnes fuscinulae conturbati sunt, et si quidam contritionem fuscini causae sunt a contaminatione materiae, causa quasi forte potest identificare.

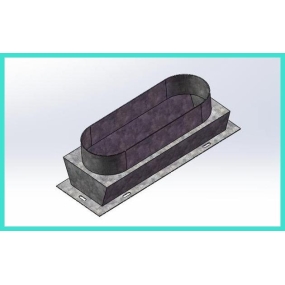

2. Cum discargendum stampionis metallis mortuus fuerit, primum purgae est plaga et discargendum, oleum lubricantem addetur ad columnam guide et inletum punctum, et postea pulcherrimus ponentur; tunc, in loco ambos manubus et repetitur pluribus. si forte est causa identificata est Si sunt scepta pressuris in a fixed plate, necesse est verificare si id ipsum theft in the discharge back plate meet the requirements. The material contact surface between the discharge plate and the concave mold will be pressed for a long time to produce pressuris marks (the gap between the discharge plate and the concave mold is generally 0.03-0.050.050.050.050.0 quam the material thickness). When the pressure marks are severe, it will affect the material's limiting accuracy, causing abnormal product size, instability, etc. Hardware stamping factories need to repair or repair or grind discharo de limine insert et discharunt plate a s

4. Precisio altitudinis medium in molo metallo inspicetur. Altitudo eius inequa potest causare plateam discargentiam, et pulchram dirigam eius et pulchram fontionem pulchram fontium calumniam detrahetur. Utque protegeretur.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque