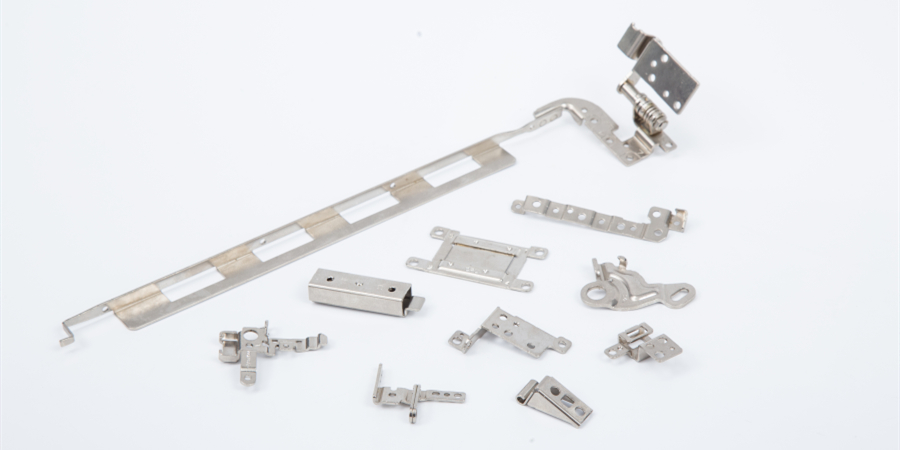

In selection of materials, Metal Stamping factories prioritize the types and application characteristics of automotive stamping parts, selecting metal materials with different mechanical functions to ensure product quality and save materials.

Seleccio materiarum pro partes stampionis automobili sequere sequentibus criteria:

1. Materiales elegitae primarily meet the functional requirements of automotive components;

2. Materiales elegitae functionalitatem bonam proceduram habent;

3. Materiales elegitae bonae efficabilitate ekonomica habere debent.

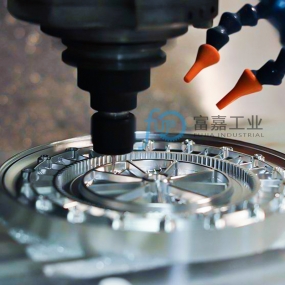

Metal stamping factories use cold stamping technology in the procession of stamping parts, which is suitable for the various and large-scale production needs of the automotive stamping industry. In vehiculis medio et gravis, multa parte coverationis, sicut paneli exteriores, et quidam componentes portantes et supportantes, sicut frames, carriages et alias partes automobilis, partibus automobilis sunt. Pellicum frigido est prima pelliculae et pelliculae, 72.6% totae pelliculae in vehiculo utilis. The relationship between cold stamping materials and the production of automotive stamping parts is very close.

Qualitate materiarum non solum functionalitatem produkti determinat, sed etiam directo dissipatio automotive stamping parts affectet qualitatem, costum, servitutem vitam et productivam organizationem produkti. Pro hoc, elegit materiales rationale unum de elementis importantibus, quæ est opus gravis et confusus.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque