Bullets are a common product in metallic stamping factories, and commonly used materials include stainless steel, bronze, and other materials. However, due to the different materials used, bullet pieces have different properties. Next, EMAR Precision will introduce the characteristics of different materials used in bullet pieces.

Stainless steel shrapnel can undergo significant elastic deformation under load, and mechanical or kinetic energy can be converted into deformation energy. After unloading, the deformation disappears and returns to its original state, converting deformation energy into mechanical or kinetic energy. Such shrapnel has high elastic limit, fatigue limit, impact toughness, as well as good temperature resistance and corrosion resistance.

Metal Domus

Post calorem trationem et frigidam tensilem indurabitur, calapnel 65mnum elastis steelis erit alta fortitudo, fortitudo et plasticitate. Pro partes mecanicas resistentes induri potest.

Choosing 70 # steel is relatively cheap and easy to source, but it has the disadvantage of losing elasticity after repeated deformation, and cannot work properly at 130 °C. Pro pretio pretioso suo, fabricatores saepe eam quam materia brusca fertilibus utilit.

Bronze has the characteristics of low melting point, high rigidity, strong formability, wear resistance, corrosion resistance, and bright color. It has excellent resilience and can be compressed up to 70% of its height. It can resist 100000 times without deformation; High compressive strength, capable of two directional repeated compression; Fatigue resistance; Easy to electroplate and welded; Excellent conductivitate; Ultra low permeability. Sharapnel bronze saepe utilitur quam material shielding for electronic devices.

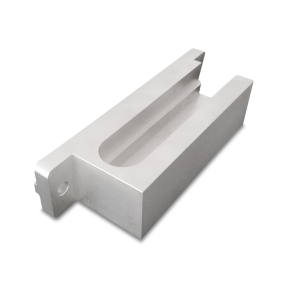

Bronze shrapnel

When selecting materials for shrapnel, it is important to consider factors such as usage, importance, load properties, size, cycling characteristics, working temperature, surrounding media, as well as processing, heat treatment, economy, etc., in order to achieve twice the result with half the effort.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque