Post processionem partium stampionis metallorum, fabricae stampionis metallorum generale faciunt tractament superficiem ut prohibetur oxidationem et alios conditiones ex quo tempore occurrere. Aspectus partium stampionis metallorum generale sicut tractat:

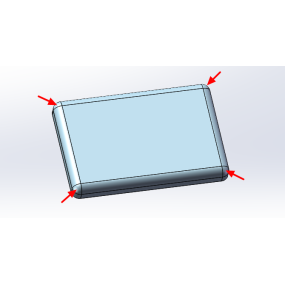

1. Superficie polishing processing: Surfacie polishing processing is generally used in daily necessities. After deburring the surface of Metal Stamping products, for example, some metal stamping parts have sharp edges and corners. For this type of stamping part, we usually polish it to make the sharp ends and corners smooth; @@000 2. Spray painting processing: Generally, metal stamping factories use spray painting processing when producing large hardware products. After spray painting processing, hardware parts are used to prevent rusting, such as daily necessities and electrical casings;

3. Electroplating: Electroplating is also the most widely used processing technology for metal stamping parts. After electroplating the surface of the metal stamping parts, it can ensure that the products will not mold or rust during long-term use. Electroplating is generally used for screws, metal stamping parts, battery cells, car parts, etc.

Post quaecumque tractament superficie potest evadere problemas oxidation is super superficiem partium pulsavorum in quibus caliginis temporis, sicut pluvia. Haec est positio victorii e clientibus et fabricationibus imprentariis hardware.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque