The manufacturing of medical equipment is a highly precise and complex process, therefore industrial automation technology has long been involved. Automatatis processing of sheet metal medical equipment is an important direction among them.

Aplicatio automation is in fabricatione medicorum crescere expandit et facta est magna orientatio in progressione futurae fabricationis medicorum medicorum.

1,The advantages of automated processing technology

Compared to traditional manual processing methods, automated processing technology has the following advantages:

One is to improve production efficiency, which can achieve 24 hours uninterrupted production and significantly improve production efficiency.

Secundus est meliorare precision et qualitatem. Equatoria automatica processionis habet altam precision, bonam stabilitatem, et altam precision, quae significantem meliora est qualitatem et reliabilitatem produktorum.

Tertia est reddere praedas labor is. Utilium automaticae fabricationis operationes manus reddere potest, inferiores praedas laboris, et competitivitatem industriorum elevare.

2,The characteristics of sheet metal medical equipment

Sheet metal medical equipment refers to medical equipment made of metal materials such as sheet metal, such as hospital beds, operating tables, medical vehicles, clean workstations, etc.

Haec apparentia semper sequentes characteres habent:

1. Precisio alta: Equatoria metalla medica usualmus manufactura alta precision requirit, ut stabilitatem et reliabilitatem equipentiae assecurat.

2. Fortitudo alta: Equatoria metalla doctrinae lapides longa tempora utilis et cargas gravis resistere oportet, et alta fortitudo et durabilitate habere oportet.

3. Exquisite appearance: Sheet metal medical equipment usually requires exquisite appearance to enhance the image and user experience of the equipment.

3,The application of automated processing technology in the manufacturing of sheet metal medical equipment

The application of automated processing technology in the manufacture of sheet metal medical equipment is very extensive, mainly reflected in the following aspects:

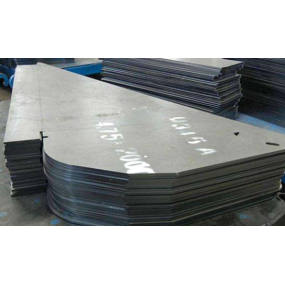

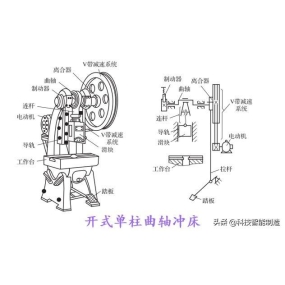

1. Sheet metal material cutting and processing: Sheet metal material cutting is an important part of sheet metal medical equipment manufacturing. Automated cutting equipment can achieve high-precision and high-efficiency cutting, improve production efficiency and product quality.

2. Sheet metal welding processing: Welding in sheet metal medical equipment is also an important link. Automated welding equipment can achieve high-precision and high-efficiency welding, improve production efficiency and product quality.

3. Sheet metal bending processing: Bending processing in sheet metal medical equipment is also an important link. Automated bending equipment can achieve high-precision and high-efficiency bending, improve production efficiency and product quality.

4. Sheet metal surface treatment: Surface treatment in sheet metal medical equipment is also an important part. Automated surface treatment equipment can achieve high-precision and high-efficiency surface treatment, improve product appearance quality and reliability.

4,The future trend of automated processing of sheet metal medical equipment

In futuro, cum continuo expansione mercantis medicorum et increasing demand for medical equipment quality, automatic processing of sheet metal medical equipment will become the mainstream trend in medical equipment manufacturing. Application of automated processing technology in the manufacture of sheet metal medical equipment will become increasingly widespread, and the accuracy, efficiency and reliability of automated processing equipment will continue to improve.

In summario, automated processing of sheet metal medical equipment is an important direction for future medical equipment manufacturing, with broad development prospects. Enterprises should actively introduce automated processing equipment to improve production efficiency and product quality, in order to meet market demand.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque