Prosecutio metallorum folia est fabricationis materiales metallorum utilizationis, saepe in diversis agris, quasi fabricatio automotiva, fabricatione domus appliantiae, aerospace, etc. Scisne fluxum metallorum artificium? The editor of the sheet processing company will introduce it below.

Procedus fluxus prima sequentes gradus includet:

1. Design and Planning: In the process of Sheet Metal Processing, product design and planning need to be carried out first. Designers draw product structure and process diagrams based on customer needs and product functional requirements. Haec gradus crucial est et directe determinat progressum subsequent is processionis.

2. Material selection and pretreatment: After determining the product design, suitable metal materials need to be selected for processing. Materiae metallici communes metallici aeneae, aluminium alloy, coper, etc. Prius processionis materiae selectae praepositi sunt, sicut mundatio, removo masculini, etc., ut certem quod superficie produkti munda est.

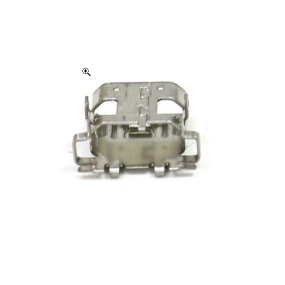

3. Cut and Forming: Next step is to cut and form the metal material. The commonly used cutting methods include laser cutting, flame cutting, plasma cutting, etc. Procedus formationis includet sculpendum, bending, extendendum et ceteros prosessos ut materiales metallos in formam et granditudinem desiderantur.

4. Gravitatio et ecclesia: Postquam secitur et formatur, necesse est omnem componentem rapere et congregare. Prosecutiones fermenta include spot welding, gas shielded welding, soldering, etc., to ensure that each component is firmly connected. Assembly est procesus inter diversos componentes combinationis secundum diagrammas design et debugging et inspectionem.

5. Surface treatment: In order to increase the aesthetics and corrosion resistance of the product, surface treatment is often required. Common surface treatment methods include spraying, coating, polishing, etc., to make the product surface smooth, uniform and brightly colored.

6. Inspectio et Qualitates Control: Proximus gradus ZUI est ad inspectionem et kontrolam qualitatem produktorum processorum. Inspecting the process and equipment, ensure that the product meets the design requirements and meets the quality standards required by the customer.

In summary, the process flow of sheet metal processing includes design planning, material selection and pretreatment, cutting and forming, welding and assembly, surface treatment, inspection and quality control, etc. Each step needs to be strictly executed to ensure the quality and performance of ZUI final products. In the actual processing process, experienced processing technicians and advanced processing equipment are also important factors in ensuring product quality.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque