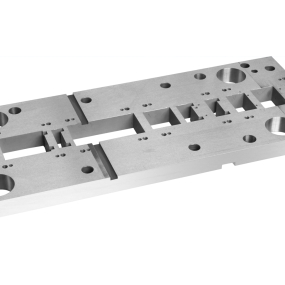

Prius quam partibus pulseris aluminium producet et processant, fabricae pulseris cognoscere sunt characteribus materialum aluminium et quomodo adprehendere adversorum phenomenas in processo pulseris

1. Materium Aluminium relativamente tenens est et mollus facilis est blocare, ergo cum fabricatione mollus ad positionem spatiarum, consilium est ponere spatias cum angularibus materiae densitate 10%. Profunditudine recta 2mm rectius est ad extremum secendi, et taper 0.8-1 graduum convenit;

2. Pro brittlentia et facile fracta aluminium materiae, sublime in reverso colligatione, consilium est non facire pressionem trabem. Etiam si necesse est, trabem amplius et amplius fieri. When processing aluminum stamping parts, stamping factories require slow wire cutting for the cutting edge to prevent burrs and uneven material dropping. Aluminum parts easily generate high temperatures, so the hardness of the mold punch used should be above 60 degrees, and at least SKD11 material should be used;

4. In order to stamp factories to process aluminum stamping parts well and reduce the defect rate, the first step is to clean them, including molds, punch tables, assembly lines and packaging materials. It is necessary to ensure that there are no sharp objects or dirt.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque