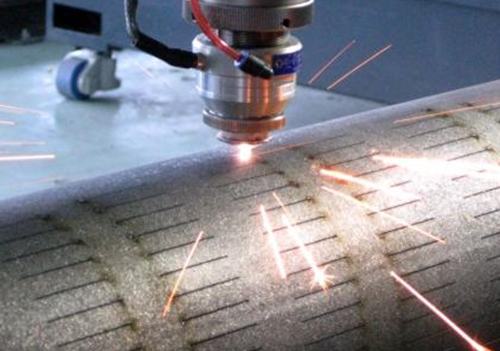

Laser cutting machines have very good cutting effects, with obvious advantages in flexible processing compared to traditional cutting, saving time and manpower, and being efficient and high-precision. Pro increasing use of metal laser cutting machines, they are applied in industries such as Sheet Metal Processing, aviation, electronics, electrical appliances, and kitchenware. Below, the editor will introduce how to use a laser cutting machine to achieve good cutting results.

1. System cooling needs to be grounded, and the water tank and waterway should be cleaned regularly. The temperature control point of the refrigeration temperature control water tank should be fair, otherwise it will cause easy damage to the laser tube, decrease in condensation power, detachment of the cold water head of the tube, greatly shortened the service life, and sometimes fail to work, resulting in continuous tube replacement.

2. Installationis punctus laseris tubae laseris computationis rationalis esse debet, et punctus supportationis est 1/4 longitudinis totae tubae laseris, alioquin modus laseris tubae dissipabit, et aliquid functionis temporalis causabit punctum pluribus punctis, resultat in diminutionem laseris potentiae quae non potest satisficere requiribus, causabit continuum replacionem tubae.

3. Aquae conservatio regulare inspicetur et purgatur. Aquae frigida saepe non potest fluctum protectionem aquae fluctum, aut protectionem aquae fluctum non resetat. Metodos curtis circulationis non oportet ad solutionem problemas urgentes solvere.

4. Apparatio suctionis inspicetur et mundabitur regular, et ducta ventilatorum purgatur Otherwise, a lot of smoke and dust cannot be discharged, severely and rapidly polluting the lenses and laser tubes, causing easy oxidation of various mechanical and electronic components and poor contact.

5. Focus lens et reflexionis inspectionis post tempus operandum faciem febris habebit, et superficie lentibus colorem et rustum mutabit. Peeling and cracking are all objects that need to be replaced, especially for many customers who use large air pumps and compressors, which quickly accumulate water on the focusing lens. Therefore, it is necessary to check the cleanness and quality of the lens optical path system on time.

6. Ambientia laborantis machinae caederis laserorum non esse multo difficile. Si temperatura ambienta superest 30 gradus et inferior 18 gradus, multa pulvis et contaminatio aeris gravis erit, quæ maquinam serio detrimetur et multiplicabit tempus defectus; Componentes electricae ad problemas in humilitate environamentibus sunt.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque