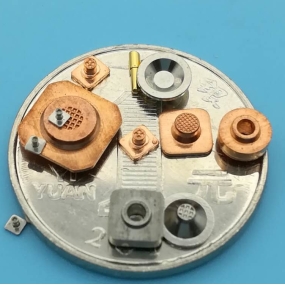

Omnia industria proprie standardi habet, et sicut industria fabricationis, aeque est. Quid sunt standardi partibus metallicis processionis? Dongguan EMAR Precision Electronic Technology Co., Ltd. has been focusing on the customization and wholesale of high-precision products for 30 years. We have some insights into the standards for processing Metal Stamping parts. Now, let EMAR Precision share with you.

1、 Strict testing mechanisms must be established in the production process of metal stamping parts. The first sample of metal stamping parts must be inspected comprehensively, and only after passing the inspection standards can they be put into production and manufacturing. At the same time, inspections must be improved, and accidents must be handled properly.

2、 Adhere to the mechanism of civilized production and manufacturing, such as using suitable workstation equipment for the transmission of workpieces and blanks, otherwise it will crush and scratch the surface of the product workpiece, affecting the surface quality of the metal stamping parts.

3、 During the stamping process, it is necessary to ensure the cleanliness of the mold cavity, and the workplace should be organized in an orderly manner. After production and processing, the metal stamping parts should be placed neatly.

4、 Raw materials must comply with the specified technical standards (strict inspection of the specifications and models of raw materials, and comprehensive testing of metal stamping parts with high dimensional precision and surface quality requirements under standard conditions).

5、 All aspects of the production process regulations for metal stamping parts should be strictly followed in all aspects.

6,The hardware stamping equipment used must ensure regular operation without any abnormal conditions.

The above points about the specifications for processing metal stamping parts are our years of experience sharing, hoping to help everyone. If you want to learn more about metal stamping parts, please feel free to consult us at any time.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque