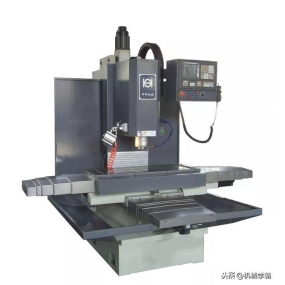

Sheet Metal Processing is a very common metal processing method that is widely used in the field of production and manufacturing. However, there are often some problems encountered during sheet metal processing that affect production efficiency and product quality. Next, let's explore common problems and solutions for sheet metal processing manufacturers.

Problem 1: Improper material selection leads to processing difficulties

Variae typi materiae in processione metallorum utili sunt, et optio materiae significat influentiam super technologiam processionis. Si materia cum alta difficultate et paupere difficultate selecta fuerint, difficultatem processionis et facile ad problemas qualitatis, quales cracking et deformatione inducet. Solutione est eligere adequatum substantiam basem super necessitatibus constituentes, considering factores such as strength, hardness, and plasticity.

Problem 2: Improper setting of process parameters leads to low production efficiency

The process parameter settings in sheet metal processing directly affect production efficiency and product quality. If the process parameters are set improperly, it can lead to slow processing speed, excessive cutting load, and even damage to the equipment. The solution is to adjust the appropriate process parameters during sheet metal processing based on factors such as material properties and processing difficulty, to ensure processing efficiency and product quality.

Problem a 3: Facilitate arma temporale conservare ducit ad opera malfunctiones

Sheet metal processing equipment is an important tool in the production process, and its normal operation directly affects processing efficiency and product quality. Si non est tempus aut standardisum equipamentum, facile est causare defectum equipmentorum et influentiam ad produkciju normalem. Solutione est regulare inspicere et custodire instrumentum ut in bono opus esse et reddere occurrentiam malfunctionum.

Problema 4: Low technical level of personnel makes it difficult to master the process

The sheet metal processing technology is complex and requires high operational requirements, requiring operators to have rich experience and skills. Si non est altus nivel tecnicae personalis, facile potest difficultatem inducere in manu procedentis et ad qualitatem produktorum uticare. Solutione est meliora praefectionis praepositorum, semper intellegentia technica et operabilitates suas et praesens progressum procedentis.

In summary, sheet metal processing manufacturers need to pay attention to material selection, process parameter settings, equipment maintenance, and personnel training in order to effectively solve common problems, improve production efficiency and product quality, and ensure smooth production. Spero quod supra contentio utile sit tibi.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque