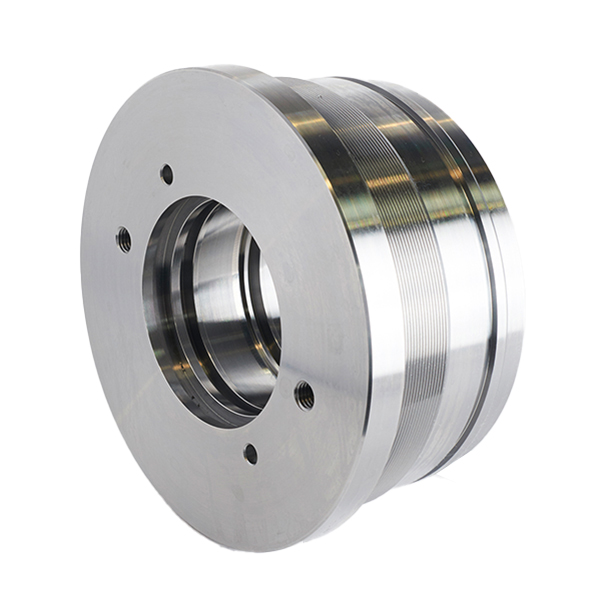

CNC machinatura quinque axis modo machinatura alta precision et alta efficientia est, si autem aliquid factores clave non considerantur, potest problema machinaturae innecessaria occurrere. Hic sunt quosdam metodes ut non necessarii problemas machinaturae evadere:  @ @ 000 & @ 9312; Programatio rationale et plantatio pathis: Ut software professional CAM ut optimizationem semitarum programmationis et reducam numerum interfectorum instrumentorum in et out. Avoid sharp corners or changes in depth to reduce stress concentration and mechanical impact on the tool. Reasonably set cutting parameters such as cutting speed, feed rate, and cutting depth based on the workpiece material and tool type Regularly calibrate fixtures and machine tools to ensure positioning accuracy Tool selection and maintenance: Choose the appropriate tool type and material based on the workpiece material and processing requirements. Regular check the wear of cutting tools and replace severely worn tools in a timely manner. Kolant veya lubrikant kullanın araçların temperature ve friksiyonu düşürmek için ve araçların hayatını uzatmak için kullanın. Machine tool maintenance and inspection: Regularly clean and maintain the machine tool to ensure the normal operation of all components. Check the accuracy and stability of the machine tool, such as the accuracy of components such as guide rails and spindles Monitoring and adjustment during the processing: Use online detection equipment to monitor the size, shape and surface quality in real-time during the processing. Adjust cutting parameters or modify programming paths in a timely manner based on monitoring results to address potential issues Skills and training of operators: Operators should have rich experience and skills in CNC Machining. Regular train operators to improve their understanding and control ability of the machining process Improvement and compliance with process documents: Develop detailed process documents, including machining steps, cutting parameters, tool selection, etc.

@ @ 000 & @ 9312; Programatio rationale et plantatio pathis: Ut software professional CAM ut optimizationem semitarum programmationis et reducam numerum interfectorum instrumentorum in et out. Avoid sharp corners or changes in depth to reduce stress concentration and mechanical impact on the tool. Reasonably set cutting parameters such as cutting speed, feed rate, and cutting depth based on the workpiece material and tool type Regularly calibrate fixtures and machine tools to ensure positioning accuracy Tool selection and maintenance: Choose the appropriate tool type and material based on the workpiece material and processing requirements. Regular check the wear of cutting tools and replace severely worn tools in a timely manner. Kolant veya lubrikant kullanın araçların temperature ve friksiyonu düşürmek için ve araçların hayatını uzatmak için kullanın. Machine tool maintenance and inspection: Regularly clean and maintain the machine tool to ensure the normal operation of all components. Check the accuracy and stability of the machine tool, such as the accuracy of components such as guide rails and spindles Monitoring and adjustment during the processing: Use online detection equipment to monitor the size, shape and surface quality in real-time during the processing. Adjust cutting parameters or modify programming paths in a timely manner based on monitoring results to address potential issues Skills and training of operators: Operators should have rich experience and skills in CNC Machining. Regular train operators to improve their understanding and control ability of the machining process Improvement and compliance with process documents: Develop detailed process documents, including machining steps, cutting parameters, tool selection, etc.

Salve! Welcome to the EMAR company website!

Latin

Latin » »

» »

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole