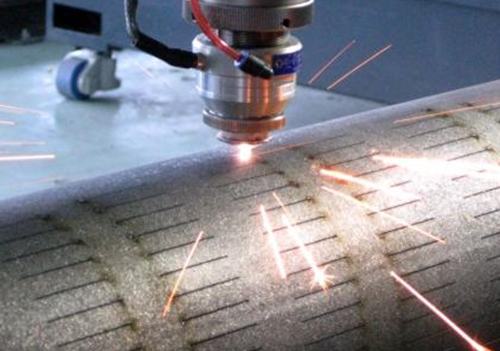

Laser cutting machines are widely popular in the processing industry due to their cutting characteristics, which leads to a large number of customer inquiries about various issues related to laser cutting machines. Among them, material consumption accounts for the majority. Today, Shenyang laser cutting manufacturers will talk about this issue for everyone.

Tres speciosa prima sunt ex laserorum machinis, id est laserorum tubas, reflectores metallos, et oxygenum aut gasum nitrogenem.

When laser cutting machines are used to cut metals, oxygen or nitrogen auxiliary gas needs to be added to achieve slag free cutting of metal. Si non-metallic is materiae, sicut folia acrylicia, necesse est, lentes focus replaci, quae melius est laser tubam utilizati.

Et propter hoc mentionatum est supra quoniam laserorum tubae sunt materiae consumabiles, quia post aliud tempore utilis, function a laserorum tubarum infirmare incipiet et ultimo non potest usare. Lentes telefocatores melior poterunt materiales claudicatores claudicatores secere. Saying these is to enable customers who use laser hybrid cutting machines to save on material consumption costs, and also to perform metal and non-metal cutting, improving cutting efficiency and speed.

Quantum oxygenum aut nitrogum consumitur quando metallum secant? Continuous processing, usually with a standard bottle of oxygen or nitrogen, can take 3 to 4 hours for processing. Si 60m per horam currere potest, tunc botella oxygeni aut nitrogenae 180m usque 240m procedere potest.

If we further subdivide it, a cutting material with a circumference of 50cm would result in 360 to 480 workpieces. And a bottle of oxygen or nitrogen, with a market price of 20 yuan per bottle, and further divided, the cost of oxygen consumption is basically a normal consumption. So, for the oxygen consumption of this laser hybrid cutting machine, its cost is very low and can be basically ignored when divided into individual workpieces.

So, when purchasing a laser cutting machine, the cost of consuming materials can be basically ignored. Quia si laser tuba pluribus milibus yuan costat, vita servitutis eius long a est, et cum pariter dividitur, basically nulla costa est. Non mentionare minimo consummatio oxygeni costis.

The content of the article is sourced from the internet. If you have any questions, please contact me to delete it!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque