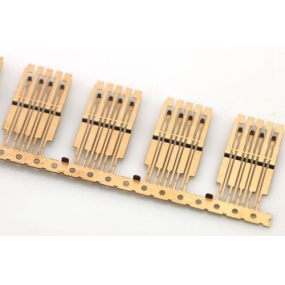

Firstly, the cutting comparison between modern five axis CNC Machining centers and traditional three-axis CNC machining centers. A five axis machining center is a traditional three-axis machining center that completes five axis linkage machining by adding a rotating axis to the X-axis. The rotation axis that rotates around the X axis is defined as the A rotation axis. The processing range of the A axis is between 30 and negative 120. A rotary table is set in the middle of the A rotation axis, which can rotate around the Z axis and is commonly referred to as the C rotation axis. The working range of the C rotation axis is 360 revolutions, and the combination of these two rotation axes can complete the machining of all surfaces except for the installation surface in one workpiece clamping, with a smaller division value of 0.001, so that there is no blind spot on the machining surface.

Secondly, when machining the side of the workpiece, the tool length of a five axis CNC machining center is much shorter than that of a three-axis machining center, which greatly improves rigidity and machining accuracy. When dealing with chaotic and heterogeneous spatial structures, the linear motion of a three-axis machining center is often inadequate, while a five axis linkage machining center can complete the machining of special parts through the deflection angles of the A and C axes.

Then, the five axis linkage machining skill also has the characteristics of simple spindle structure, good spindle rigidity, and relatively low production cost. Quando pretium quinque asses CNC machinatorium centrorum nunc altum est, in futuro, cum continuo profunditate interrogationis machinatorium, quinque asses machinatorium CNC propinquationes amplius erunt.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque