Con opus modernis industriae disveloppationis, futurae paneli in modum composite et functionalis movebuntur. Due to the increasing emphasis on environmental protection in society, coated sheets and lightweight materials such as aluminum alloy sheets for automobiles will be more widely used, but traditional spot welding technology has greatly hindered this development. Therefore, how to handle the connection problem of these new types of sheets well is not only crucial for the widespread application of these sheets in precision stamping parts processing factories, but also crucial for improving the quality and reducing costs of modern industrial products.

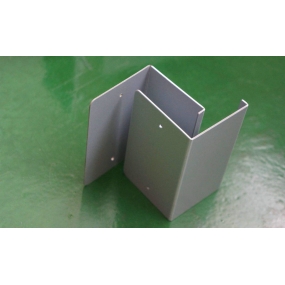

The commonly used connection methods for stamping parts in precision stamping factories include:

1. Connexio bite connexio connexionis: Bite connexio est method connexionis lateribus metallorum pulsatum per colligandum et pulsatum connexionis. Connexio bite connexio non necessit equipamentum speciosum, et habet bonam finenes et est valde fidelissima. Conventum in structuris metallorum foliarum utilitur cum densitate minus quam 1MM, sicut metodo coperii ferreorum communa.  2. Riveting: When precision stamped parts cannot meet the expected requirements. Usum est connectere duos partes in unum, quæ appellamus welding. Utilissima utilizata sunt argon arca welding, electric welding, gas welding, etc. Riveting is non removable connection method formed by rivers. The structure of riveting has the characteristics of uniform and reliable force transmission, resistance, good plasticity, and easy maintenance. Therefore, it is used for the connection of certain dissimilar metals and welding metals (such as aluminum alloys);

2. Riveting: When precision stamped parts cannot meet the expected requirements. Usum est connectere duos partes in unum, quæ appellamus welding. Utilissima utilizata sunt argon arca welding, electric welding, gas welding, etc. Riveting is non removable connection method formed by rivers. The structure of riveting has the characteristics of uniform and reliable force transmission, resistance, good plasticity, and easy maintenance. Therefore, it is used for the connection of certain dissimilar metals and welding metals (such as aluminum alloys);

3. Connexio Screw: generally used for detachable structures, characterized by simple construction, easy assembly and disassembly, low cost, and wide application;

4. Pre embedded connection: It is to press screws, bolts or nuts into precision stamped parts. Pre embedded bolts generally do not have any problems because they are specially designed with a groove above the hexagonal head. When the hexagonal head is pressed in, the material on the board will squeeze into the groove and can be fixed on its own. But screws are different. Generally, the screws we choose are not specially made and do not have kneading grooves. Therefore, when the screw is pressed in, there is no place for the kneading material to go. Due to the kneading of the material, it is difficult to control the perpendicularity between the screw and the sheet metal plane. So, when installing other parts, it is often difficult to assemble, and the longer the screw, the more difficult it is to control. At this point, there is no need to use pre embedded forms, it is better to directly connect them with screws.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque