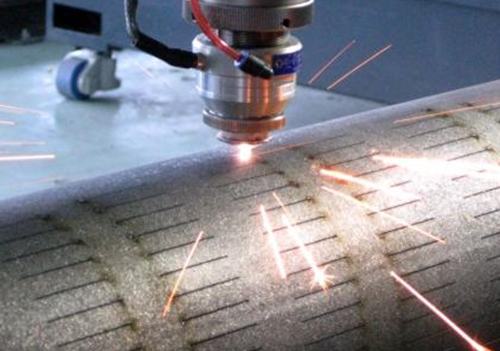

Potesne aqua caeci replace laser cuta? Below, Shenyang laser cutting manufacturer will briefly introduce the comparison between water cutting and laser cutting:

1,Advantages of water cutting:

1) Potent omnia materia (inclusive materiales reflective, materiales composite, materiales sensitive, etc. ut lasers non possunt aut difficiles secere, sicut lapides, alloys, etc.)

2) Deitudinem sequitur valde profundum potest. Like 100MM or even thicker materials.

3) Cutting will not cause thermal deformation. Exalta precisa cuta.

4) It will not change the texture of the material around the cutting seam (laser belongs to thermal cutting and will change the texture around the cutting area).

2,Disadvantages of water cutting:

Speeda valde lenta est. Non adequatum ad productionem massae.

3, Advantages of Laser:

1) Fast speed. Pro productione massae utilisar potest.

4,Disadvantages of Laser:

1) The application of laser cutting carbon steel in industry is generally below 20MM. Capacitatem cutationis generale subter 40mm est. The industrial application of stainless steel is generally below 16mm, and the cutting ability is generally below 25mm.

2) Laser verumtamen multa materia succidere potest, sed adhuc aliquid defectus habet comparationes aquae succidentiae, sicut materia cum forte reflexibilitate, marmor et cetera.

3) Non est tam bona facie succidentis quam succidentis aquae, quam densior materia, quam manifestior est.

In summario, the efficiency of water jet cutting and laser cutting is vastly different and cannot replace laser cutting.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque