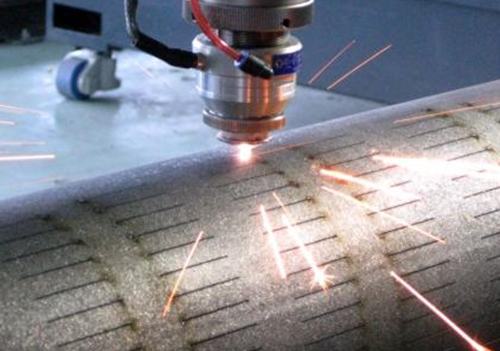

Sequentes sunt precautiones quae accipientur in laser cuto processione:

1. Laser cutting causes rushing on the surface of stainless steel materials.

When there is rust on the surface of our stainless steel material, it is difficult to cut through the material and the final processing effect will be poor. Quando in superficie materiae rota est, reddet laser reddere ad nozzlem, quod facile est nozzle detrimere. Problema altitudinis excessive etiam potest detrimere componentes. Quando nozzle mutabit, laser succidens deviabit, quod est situatio nozzlei incorrecta. Hoc etiam detrimetur systemam opticam et protectilem, et etiam potest inducere ad processandum accidentum explosion is. So the rust removal work on the surface of the material must be done well before cutting.

2. Laser cutting stainless steel material surface painting

Paintura superficium sterilis stainless generale non est communa, sed etiam nos oportet attention, quia pinctus generale substantia toxic a est, qua facile fumum in processione potest facile facile prodere, quod est pessimum sanitate hominis. Pro hoc, cum materiales sterilis pinctus pinctum fertilissimam, oportet delere pinctum superficie.

3. Laser cutting machine with stainless steel material surface coating

Situatio superficie fertilis stainless fertilis saepe occurrit in nostro cotidie processione, sed non est fessibile si sequeremus tradiciones technicas processionis. When cutting stainless steel with equipment, film cutting technology is generally used. To ensure that the film is not damaged, we usually cut the side of the film that is not coated downwards.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque