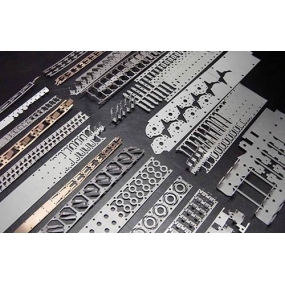

Precision Sheet Metal Processing is a high-precision, high demand metal processing method widely used in fields such as electronics, communications, health care and automotive. Cum fabricationem metallorum precisium fecerint, oportet aliquid importante sententiam communam magistrare qualitatem et efficientiam processionis. Sequentes cognoscentia communa sunt, quam cognoscetur quando lapides metallis processatur precision:

1. Material selection: Different materials are suitable for different processing needs, and commonly used sheet metal materials include stainless steel, copper, aluminum, nickel alloys, etc. Ut materiales elegit, factores, quasi proprietates mechanicae, resistentia corrosionis, et processionis exercitus considerari sunt.

2. Design specifications: Before precision sheet metal processing, detailed design specifications are required, including requirements for dimensions, shape, processing technology, etc. The rationality of design specifications directly affects the quality and processing efficiency of products.

3. Processing technology: Precision sheet metal processing usually includes cutting, stamping, bending, welding and other processes. When processing, it is necessary to choose the appropriate processing technology according to the specific product requirements to ensure the accuracy and quality of the product.

4. Eleccio Equipmentorum: Elegans instrumenta adequa factor est in praesentia qualitatis lapides metallis. Common equipment includes CNC punching machines, CNC shearing machines, CNC bending machines, etc.

5. Testum et inspectionem: Post processionem metallorum lapides precisius, testum et inspectionem strictum est, ut asseguratur qualitatem produktorum quod praecepta sunt. Metodos probationis Common include coordinate measurement, hardness testing, and visual inspection.

6. Post processing technology: After precision sheet metal processing, surface treatment, cleaning, assembly and other post-processing processes may be required. The selection and execution of post-processing techniques have a significant impact on the quality and appearance of the product.

7. Qualitates management: In process of precision sheet metal processing, it is necessary to establish a strict quality management system, including quality control, quality inspection, quality improvement, and other aspects. Only with a sound quality management system can we ensure stable product quality and continuous improvement.

In breve, mastering the above common sense is necessary for precision sheet metal processing. At the same time, continuous learning and practice are needed to improve one's processing technology and management level, in order to meet customer needs and market competition. Spero quod supra sit adiutor tibi, gratias tibi!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque