With the refinement of industrial electronic products, various industries have increasingly high requirements for Metal Stamping parts, including the shape of metal stamping parts. In process stampionis metallorum facile est facile facie phenomena fluctus et twisting is, quae ad qualitatem produktorum influent. Hoc articulum summarizet experimentum communicatum cum omnibus: Cur metal stamping parts experience flipping and twisting? Quomodo problemam solvere?

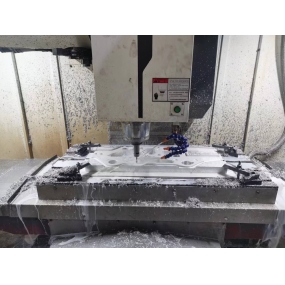

Metal stamping parts are formed in a progressive die by punching the remaining material around the metal stamping part to create its shape. Impectus punctionis est causa principalis rotationis et rotationis partibus metallis. During punching, a causa presence of punching gaps, the material is stretched on one side of the die (warping up) and compressed on the side near the punch. Ut plateam discharge utilizat materiam coherere et prohibetur materiam in latere molli ne supra moveret. At this point, the stress state of the material also changes accordingly. Quando pressure increases, materia proxima latere convex molda extentur (force compressiv tendit ad diminuendum), dum materia super faciem molda compressa est (force tensile tendit ad diminuendum). Fluctione partium metallorum ex extensione materiae superficiis fuscini causa est. Pro hoc, durante secatione, pressione et compactione, clave sunt prohibere partibus metallicis a flictione et turbatione.

Reasons and solutions for flipping and twisting of metal stamping parts:

1. Caused by burns generated during punching. Training is required for punching cutting edge, and attention should be paid to check whether the punching gap is reasonable.

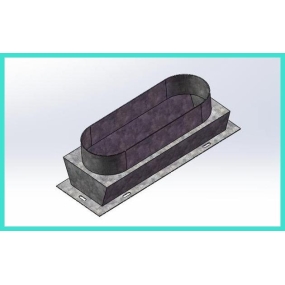

Inter proceduram segregationis, partibus claudicationis poterunt transversare aut twist, resultant in pauperem formationem post bending. Statio succidentis hoc problemam sollicitur.

3. Instabilitate partes metallorum in fermento. Mainly for U-shaped and V-shaped bending. Key to solve this problem is to perform lead positioning before and during bending, compress the material during the bending process, and prevent metal stamping parts from sliding during the bending process.

Cur partibus metallis pulserunt et pulserunt? Quomodo id solvere? Credo te iam intellegere. Impectus punching force, non rationale punching clearance, et uneven clearance sunt rationes importantes pro rotacio et rotacio partibus metallorum. Using the above methods, these problems can be effectively solved, avoiding the flipping and twisting of metal stamping parts.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque