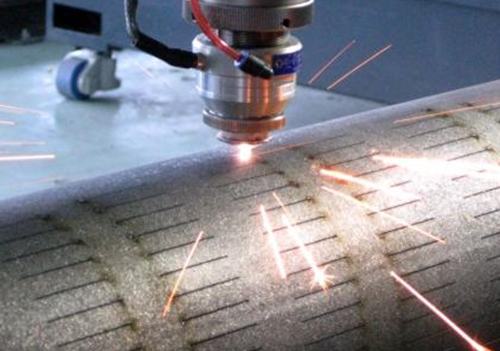

Laser cutting is currently the most widely used laser processing technology in various countries. In many fields abroad, such as automobile manufacturing and machine tool manufacturing, laser cutting is used for the processing of sheet metal parts. Con continuum meliorem qualitatem lignorum laserorum altissimi potentiae, varium processionis objecti laserorum cutationis extensivius erunt, inclusive quasi omnes metallos et non metallos materiales. Exemplo, laser cutatio potest utilizat ut tribudimentiam partes materialis cum alto duritate, angustia, et puncto conflationis, quod est etiam avantia laser cutationis.

Nowadays, laser cutting enterprises in Shenyang are mainly divided in to two categories: one is large and medium-sized manufacturing enterprises, which produce a large number of sheets that need to be cut and cut, and have strong economic and technological strength; The other type is collectively referred to as processing stations, which specialize in undertaking laser processing business externally and don't have their own leading products. On the one hand, its existence can meet the processing needs of some small and medium enterprises, and on the other side, it plays a role in promoting and demonstrating the application of laser cutting technology in the early stage.

Claves technologies laser cutationis sunt tecnologia integra lux, machinae et electriciae. Parametri ligni laseris, et exercitus et precisio machinae et systemae CNC, directe effectivitatem et qualitatem laseris cutationis influent. Precisio, efficientia, et qualitate laser cutting varia sunt cum diversis parametros, sicut cutting power, speed, frequency, material thickness, et material, ita dives experience of operators is particularly important.

1.1 Main advantages of laser cutting

(1) Good cutting quality: narrow incision width (generally 0.1-0.5mm), high precision (generally hole center distance error of 0.1-0.4mm, contour size error of 0.1-0.5mm), good surface roughness of the incision (generally Ra of 12.5-25 μ m), and the incision generally does not require secondary processing for welding.

(2) Velocitate velocitatis sectionis, ex exemplo, energia 2kW laser is, velocitas octo mm caloris carbonis fertilis est 1.6m/min; Velocitate caloris sterilis caloris cum densitate 2mm est 3,5m/min, cum parva caloris zona et minima deformatio.

(3) Clean, safe and pollution free, greatly improved the working environment for operators.

Jiangxi laser cutting non-contact optical thermal processing est et cognoscitur "omnis instrumentus potens qui nunquam extinguit". Laboratores constantly packatur aut in omni forma secere potest ut materiales raw utilizat. A causa non-contact processionis, distortio parterum processionis reducitur ad inferiorem nivellum et quanta portarum minima est.

In fact, laser cutting has also its shortcomings. In terms of accuracy and cutting surface roughness, laser cutting has not surpassed electrical machining, and in terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. In addition, it cannot perform molding, tapping, and folding like a turret punch press.

1.2 Comparison between laser cutting and punch press

Previously, the Sheet Metal Processing industry used traditional punching machines for stamping, but later developed into CNC turret punching machines and composite machine tools. With the progress of society, laser cutting technology has also been introduced in the metal processing industry, and has become a rapidly developing and widely used advanced processing method for sheet metal cutting in industry. According to informal statistics, China has accumulated over 500 laser cutting systems used in industrial production, accounting for approximately 2% of the world's total operating systems.

In the metal processing industry, laser cutting in Jiangxi is widely used for low carbon steel with a thickness of no more than 20mm and stainless steel with a thickness of 8mm. Most of the sheet metal parts have complex contour shapes and small batch sizes, such as automatic elevator structural parts, elevator panels, machine tool and grain machinery covers, various electrical cabinets, switch cabinets, textile machinery parts, engineering machinery structural parts, large motor silicon steel sheets, etc. In addition, some metal patterns, logos and fonts used in decoration, advertising and service industries can also be manufactured using laser cutting.

CNC turris punching machine suitable for mass production of products with simple shapes. Produkti electricali cabineti, communication system exchange cabinets, elevator door panels and handrail panels, steel furniture, etc. Compared with CNC bricks tower punching machines under the same cutting and stamping conditions, laser cutting machines are generally more expensive, but due to their flexibility and other advantages (such as laser cutting only needs to cut according to the drawing shape, and there is no need to manufacture molds, which shortens the production cycle). In recent years, some manufacturers have gradually realized the high efficiency it brings. In order to enhance market competitiveness, companies have purchased laser cutting machines to adapt to various types of products while owning multiple CNC brick tower punching machines. Utrum non dicens machinas laseros concidiant ad machinas punching turris CNC, magis oportet dicere inter se complementare.

2. Applicationes Typicae de laser cutting

Applicationes in agro automatico

Advanced 3D laser equipment can not only achieve cutting of car body parts, but also cutting, welding, heat treatment, cladding, and even 3D measurement of the entire car body, thus aching technical requirements that cannot be achieved by conventional processing. The 3D laser equipment of Deutsche Bahn has been successfully applied for many years in companies such as Mercedes Benz, Audi, BMW, Volkswagen, General Motors, Ford, Renault, SKODA, Opel, SAAB, VOLVO, and DaimlerChrysler.

Widely used in the aviation field

Many international aviation engine companies use 3D laser equipment for cutting and drilling high-temperature alloy materials in the burner section, and have achieved success in laser cutting of aluminum alloy materials or special materials in military and civil aircraft.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque