Processione metallorum lapidum est tertiae processionis metallorum mundi et habet multam variam applicationibus, quasi in omni industria. If the cutting process of precision metal plates (with a thickness of less than 6mm) is carried out by Sheet Metal Processing manufacturers, it is only laser cutting, plasma cutting, flame cutting, shearing, stamping etc. In medio, laser cutus in novissimis annos thrivit. In agro platearum metallorum secere potest de plateis ultra thinis micronus usque ad decem milimetrorum platearum densis. In a sense, laser cutting machines have brought a technological revolution to sheet metal processing. Compared with traditional cutting methods, laser cutting is easier to understand and learn, and has many advantages in terms of processing efficiency and the speed required by merchants in Shenyang sheet metal processing. Therefore, it is believed that laser cutting machines will become the trend of the future.

High density laser beam is used to irradiate the material to be cut, rapidly heating the material to the evaporation temperature and evaporating the pores to form pores. When the light beam moves towards the material, the hole is continuously formed as a narrow slice with a narrow width (e.g., about 0.1mm). Cutting materials - This is laser cutting, which has high efficiency, high energy density, and flexibility. It is the preferred choice for precision, speed, and efficiency in the sheet metal cutting industry.

As a precise machining method, laser cutting can cut almost all materials, including two-dimensional cutting or three-dimensional cutting of thin metallic plates. Laser in parvo puncto precisa et precisa processionis, sicut pulchra incisiones et micro cavum machinationes. In addition, it does not require tools during the processing, and it is a non-contact machine without mechanical deformation. Aliquid materiae quae tradicionally difficile sunt secere aut secere qualitate alta solvere potest per laser succidendum. Laser succidendum, sublime pro aliquid carnibus steel is succidendum, est positio incessabile.

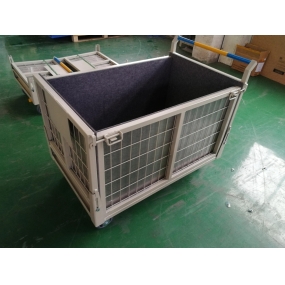

Production of sheet metal, sheet metal, profiles, pipes and other metal technologies, this process manual, general equipment and simplified or special equipment, molds, fixtures, structural metal parts, metal forming requirements, including cutting, stamping, bending, grinding, cutting, bending, riveting, welding, surface treatment and assembly.

Sheet metal is steadily growing. Currently, the China Forging Association estimates that by the end of 2012, the production of sheet metal in China had reached 2.5 million units, with sales of approximately 680 million yuan and more than 50 companies and 25000 employees. The sales revenue in 2013 was approximately 700 billion yuan, and the sales revenue in 2014 was approximately 750 million yuan.

Equipment should improve the homogenization of severe competition, system integration of sheet metal processing manufacturers, product quality, and reliability. The key feature of slow production process is that the production process still shows comparable brands with advanced foreign standards. Praeter omnes instrumentos metallicos metallicos importatus. The sheet metal processing equipment of the present invention is integrated without processing, forming a multifunctional copier for research and development in this field.

Information construction of the sheet metal industry is still undecided today. ERP et MES produktio non sunt popularis, et servi postali et municipalii maxime utili sunt ad communicationem et opus primitivarum actionibus hominis, quod magnum effectum habet ad industriam.

The accuracy, stability, and other technical indicators of local production equipment lag behind similar international products, and imported equipment is expensive. Research and development of laser cutting machines, CNC punching machines, CNC bending equipment, important functional mechanical parts, system integration, product quality and reliability, and improvement.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque