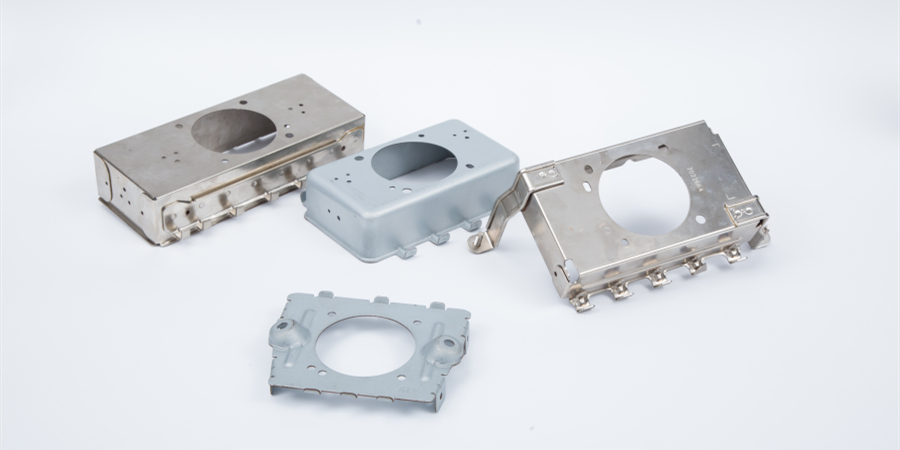

Stamping parts processing plants, processing precision stamping parts, Metal Stamping parts, automotive and motorcycle parts, etc. With the development of society, stamping parts products have spread to various industries. Some professional knowledge of stamping parts processing profession needs to be understood and grasped by our technical personnel. Today, let's take a look at the impact of edge value on stamping parts?

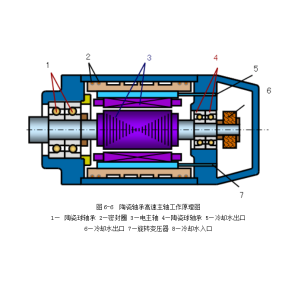

Valor anguli habet influentiam significantiam super processum secessionis et qualitatem parterum pulsavorum, it a necesse est confirmare valorem anguli rationale. Raeda nimis magna est et tempus utilization is materiae minimus est; Quando finis nimis parvus est, non sufficit fortitudo et rigiditate part is claudicationis, et facile est turbare aut disrumpere in punctione, quod non solum incrementat ardores partis punctis, sed aliquando etiam educet eam in interrumptum fusae ex uno latere, causans inequam punctionis fortem et percutientem extremum fusae. According to production calculations, the mold life is more than 50% longer with normal edge trimming than without edge trimming during punching. Factors affecting the edge value:

1. Proprietates mechanicae materiae. Valor anguli materiarum difficili minor esse potest; Valor anguli materiae mollis et brittulis superior est;

2. Material thickness. Plus denser materia, maior in angulo valor;

3. Forma et scala partium precisionis, plus complexa forma partis claudicationis, minor radius filleti, et maior valor anguli accipietur.

4. Metodos pascendi et bloquendi. Using manual feeding techniques, the edge value of the side pressure equipment can be reduced; angulo spatio laterale minor est quam illo in calamo

5. Methodum descargam. Anguis elastis discargationis minor est quam illud rigid is discargationis.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque