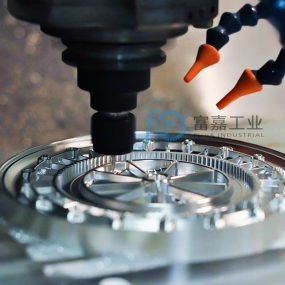

1,Positioning of test specimens

To effectively improve the accuracy of the five axis CNC Machining center, the orientation of the specimen can be adjusted. As long as the orientation of the workpiece can be in a precise cutting or machining orientation, the accuracy of the entire machining process can be improved without any errors or deviations in machining scale. Therefore, the positioning of the specimen is crucial to improve the accuracy of five axis machining.

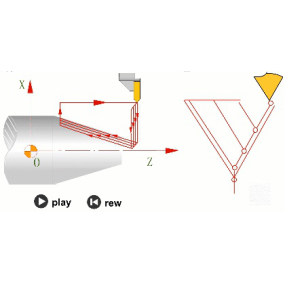

2,Cutting speed

Velocitate cutationis quinque axis machinationis centri inter proceduram machinationis etiam influent exactitatem machinationis universae equipationis. Nunc quando parametros cutationis corripiunt in accuracitate, potest successorem et velociter perfectum cutationis variorum formarum per quinque axis machinationis centrum et superior a accuracitatem facere.

3 , Servo system

Sistema servorum quinque axis CNC machining centri directo functionem accuracatis durante operationes machinarum influent. Precisio equipationis CNC includet precisitatem azimuth et repetit precisitatem positionis. Quando system a servorum et related detection systems comprehensively respondent, functionem accuracatis potest esse bonum, et non erit diferentia in positionem accuracatis, ita ut quinque axis machining centrus liber ab interferentia systemae.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque