Aviation is partes sunt produkti cum alta precision requiribus et difficultatibus procedentibus. Materiales fabricationis aviationis parterum boni sunt, quoniam multiplicatae factores, sicut pressure, temperatura, et resistentia in aere sunt. Oportum est ne aliquid problema occurrit in uso. So it is necessary to use appropriate materials for processing before processing. Before processing, it is also necessary to perform non-destructive testing on the materials to ensure the quality of the materials.

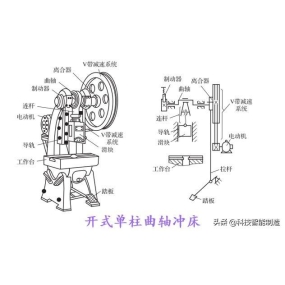

Nullus est observare et observare detalios in processione. Quia partes sicut hoc non potest benedicare, si benedicantur, potest causare problemas in uso. Pro hoc, attention in detalios in processione debet evadere abnormales situationes quae potest occurrere in processione et non potest benedicare. Cum accedere et extinguere machinam, est etiam importante custodire non collidere et assecurare quod fabrica est undamagenta. Cum processatur precision, gravis est custodire et assecurare accuracionem ut prohibere omnes problemas in tempore utilis. Processere in quinque axis potest dimittere numerum temporum clampionis in partes aviation is et multiplicare potestatem horarum operantium. Si multae flictionis sunt, errore omnis facis in quinque axis diminuere potest, et solum unus clampionis est ut perficiat processionem quinque superficium in quinque axis. It has advantages in terms of power and cost savings. When performing five axis machining, it is important to know that there should be no seismic sources near the machine tool, otherwise it may affect the stability during five axis machining.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole