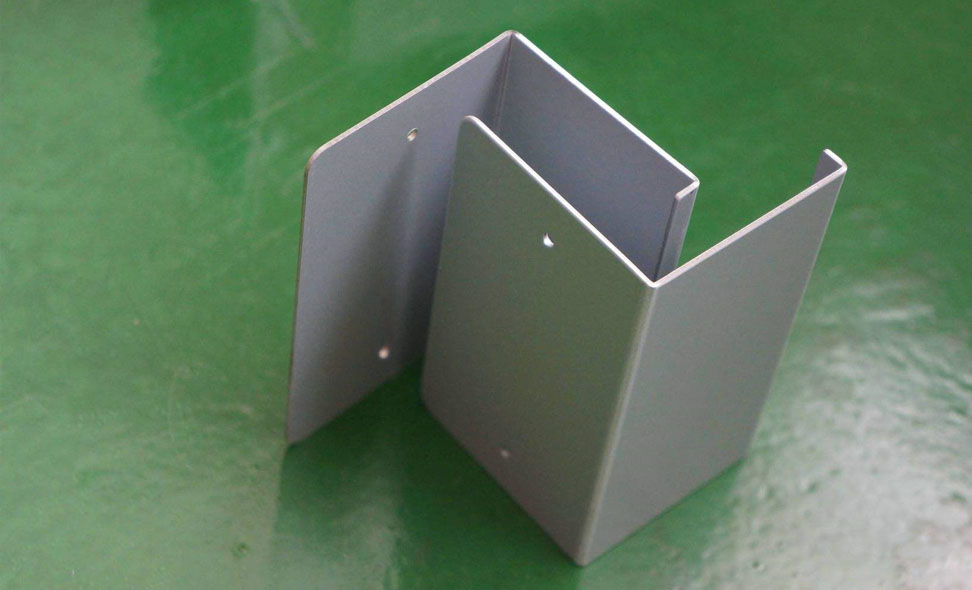

Some Metal Stamping parts factories will provide sheet metal production services, with a higher comprehensive level and a wider processing range, which is conducive to improving their overall strength. In practical work, guidance on improving operational standards based on different workflow processes can enhance employees' work efficiency.

Cum opus partibus in fabrico metallico pulsere laborare, opus est maiores opus manubus tenere, cum minores opus manu tenere potest.

When bending a workpiece with a small width and a large bending length, the operator stands on one side of the workpiece, and the front end of the workpiece is pressed by the left hand near the lower mold position. The right hand pushes the workpiece forward and stabilizes it. When bending, the right hand should hold the workpiece up and move it together. When bending, the right hand should pull the workpiece up to prevent deformation. When the bending width of the workpiece is large, the operator should stand behind the workpiece, use both hands to push the workpiece forward, and move it up together with the workpiece during forming.

3. When bending small sheet metal parts, the operators of the metal stamping parts factory should use their fingers to hold the work piece against the lower mold, and should not push the workpiece forward to prevent finger injury caused by the cultro pressing.

When the workpiece is bent, the operator holds the upper surface of the workpiece with their fingers, and the other four fingers can move the workpiece up to prevent the death from pressing fingers.

Cum creverit opus, non possint digitos super superficiem fuscinis inferioris.

6. Non potest fortitudo pulsere laborem esse, ut non efficiat inter molam, quando digiti et opera crescerent.

7. For the downward moving folding bed, during the upward movement of the worktable, the handheld workshop should rise synchronously with the worktable to prevent tilting.

postquam cresceretur manus auferetur opera et non erit collisio inter fabrum et fabrum

When bending, use a double V-shaped mold and don't press the mold down with your hands, especially for molds that are 100 mm long.

10. When operating handheld works pieces in metal stamping parts factories, it is necessary to ensure the folding balance of the sheet metal parts on both sides.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque