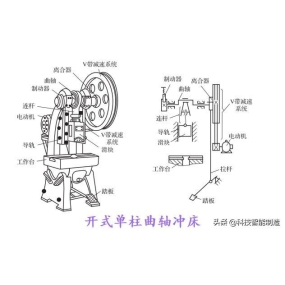

Quidam difficiles sunt in praecepto quinque tecnologiae machinaturae axis, prima propter proceduram machinaturae complexae et praecepta alta precision. Hic sunt quidam principes difficultatis punctus: 1. Planatio gressus: In quinque axis machinatione, planatio gressus est procesus complexus. Especially for parts with complex surface structures such as impellers, there are many constraints on the tool path, and the space between adjacent blades is small. During machining, collision interference is easily generated, making it difficult to automatically generate interference free tools paths. @0002. Machining accuracy control: Five axis machining requires high precision, especially when dealing with thin-walled parts, such as narrowed flow channels of impellers, relatively long blades, low stiffness, and easy deformation during CNC Machining. At the same time, the control of cutting depth is also a key technology in five axis CNC machining, and a slight error may lead to tool breakage. 3. High programming complexity: Five axis machining requires precise machining programs, which places high demands on technical expertise and programming skills. Programmatio automatica praepositum est, trajectorium instrumentorum CNC machinationis generationis, et programmas G-code generationis, quae divites experientias et scientias professionales require. 4. Equatoria alta costa: quinque instrumenta machinae maxima industriae difficiles et robustissimas tecnicas habent, sic costa instrumentorum usus maiores sunt quam instrumenta machinae tradicionales. At the same time, for certain key components, they may not be able to be manufactured domestically and rely on imports, which also increases production costs. 5. Difficulty in operation and maintenance: The operation of five axis machine tools requires complex knowledge such as multi axis linkage and spatial attitude adjustment, which requires high quality and skills from operators. Meanwhile, the maintenance of five axis machines also requires professional technicians, and once a malfunction or damage occurrit, the repair cost may be higher than that of traditional machines tools.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque