Processor et molding of PTFE plastic raw materials can be roughly divided into four types: compression molding, rolling molding, injection molding, and secondary processing. Hodie editor modicum introducet quattuor modos processionis et precautiones:

1,Fluoroplastic rolling forming

Pellicula PTFE formata est, quae in duobus procedentibus divisa potest: unidirectional rolling and multi directional rolling. After rolling treatment, PTFE film changes from its original opaque self color to a semi transparent crystal color.

Unidirectional rolling is the process of rapidly processing a film that is reheated to a transparent state by passing it through two equally rotating rollers of a rolling mill. Raportus rotationis in intervalo 1.5-2.5 controllus est, et velocitas rotationis generala 20 revolutiones per minutam est.

Multi directional rolling is a forming process in which a sintered and quenched film is placed on a rolling mill for multidirectional rolling, gradually reducing the thickness of the film. Raportus rotationis in intervalo 2-2.5 est. Temperatura drumatis inter 150-200 °C controlare debet, et pressionem vaporis in calefactione vaporis inter 0,5-0,9 megapascalos esse. Ratio rotationis est factor gravis, et nimis magnus et nimis parvus non sunt boni pro produkto. Sometimes it is necessary to repeatedly roll multiple times to press a product well.

2,Fluoroplastic compression molding

Fluoroplastica fabrica potest facire plateas, virgas, paleas, tapetas, anulos signantes, diaphragmas et partes metallis insertae.

In tres gradibus divisa est confractio: ante conflationem, sinceritatem et refrigendum. Preforming is the process of uniformly adding PTFE powder in a mold and pressing it at room temperature to form a dense preform (i.e. blank); Sinterium est processus calefactionis preformae supra calefactionis eius, dum calefactio est processus humiliationis temperaturae calefactionis ad temperaturam cubiculorum.

Aliquid fluoroplasticos formantur per pressionem unum supra temperaturam fusionis eorum. Hic typus molationis calidium pulsavum appellatur, et correspondentem pulsavum PTFE callidum appellatur.

When molding, attention should be paid to the influence of compression ratio (usually 4-6 for PTFE) and molding shrinkage rate (usually 2.6-4.5% for PTFE) on the product.

Materium raw polymerizatum est per suspensionem methodo, et pulverem mollem habentem magnitudinem particularum 20-500 micronuum preferitur. Durante pressionem, oportet "deflate" aerem. Presio prior formationis 17-35 megapascala est, et tempus tenentis dependit de densitate vacuum. Exemplo, 100mm vacuum vacuum, 15 minutis tenere debet.

Attention should be paid during sintering: the heating rate can be set at 20-120 °/hour. The larger the product, the slower the heating rate. The sintering temperature of the suspension method resin is higher, at 370-380 °C, while the sintering temperature of the dispersion method resin is lower, at 360-370 °C. The sintering temperature is higher, and the shrinkage rate and porosity increases accordingly. The sintering time should be appropriately controlled.

Cooling: Generalis, lens cooling est a rate of 15-25 °C/hour. In special cases, such as a few thin plates with a thickness less than 5 millimeters or thin-walled tubes formed by pushing, fast cooling is used.

Sometimes the product is annealed at a temperature of 100-120 °C for 4-6 hours.

3,Fluoroplastic injection molding

PFA (copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ether), also known as meltable PTFE, can be injection molded. Temperatura processionis eius relativamente latis est, usque ad 425 °C attingens, et temperatura decomposionis eius superest 450 °C. Generalis, temperatura processionis inter 330-410 °C controlatur.

PFA absorptio minima est, a 0.03%, et non est nec melior. ante injectatione, intra injectatione meliora curabitur ad circa 140.Exactly! Tempus frigidi 40-150 secundas est.

4,Secondary processing technology of fluoroplastics

Due the processing characteristics of fluoroplastics, some products are difficult to form in one go and must undergo secondary processing to obtain usable finished products. Secondary processing techniques include cutting, welding, lining, blowing, etc.

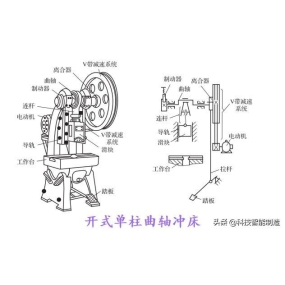

Cutting: Similar to metal cutting methods, equipment includes lathes, drilling machines, planers, etc. Ante extinguere vacuum 24 horas antequam proficisceret relinquetur.

Lining: Generally, polytetrafluoroethylene and perfluoroalkoxy (written as F4 and F46) plastic are used to line black metal pipes and pipe fittings, which can be used as chemical anti-corrosion and corrosion-resistant materials.

Blowing: Products include corrupted tubes, heat shrink tubes, heat shrink films, etc. In inflationem continuam et inflationem intermittentiam dividitur.

Ventura: divisa in duas speciosas: pressura calida et aere calida ferentes cum virgis ferentes. Presa calide fermenta ad 327 °C aut supra calefactum est in clamp speciale dissipatum et pressionem facientem ut successum fermentari possit.

Hot air welding rod welding uses PFA bars, which are heated and pressed through PFA to connect two pieces together.

The billet of F46 heat shrinkable tube is prepared by water-cooled vacuum shaping method, with a pipe stretching ratio of 3-7, a molten cone length controlled at 10-20 millimeters, an inflation mold temperature of 80-160 °C, an inflation pressure of 0.1-0.2 megapascals, and a traction line speed of 80-500 millimeters per minute. Et F4 tubae spirales inflatae sunt.

Exemplo, PTFE instrumenta machinae ducit cincturam saeculum: utilizat methodo suspension is PTFE materiae particularum optimam post crucem, transiens per sievam 20 mesh, granditudo particularum bronzerum aut pulverem aluminium 200 mesh est. Pro 100mm vacuum vacuum tenete pressionem 5 minutis, tres vices dimittite gasum in medio, calefacet a tempus 50-60 °C/hora dum sinteratur, temperaturam 320 °C temperaturam servate usque ad horam 1, et calefacet usque ad 150 °C ante removum de fornacio. Ante vacuum convertere, ad 80 °C calefacetur et calefacetur unum horam ante procedere. tapeta molla cum naphthalene sodium tractabitur, inclusive 51 gramos naphthalene, 100 millilitros tetrahydrofuranorum, et mensuram sodium metallici adequam. Tapae molae cum densitate minus quam 1 millimetri in solutione ligaminis naphthalene sodium 1-3 minutis, et tunc aqua calide 90 °C erunt.

PTFE can be co mixed with polystyrene, polyimide, and poly (p-hydroxybenzoate), and filled with graphite, molybdenum disulfide, bronze powder, etc. It can be applied to hydraulic gates, and fluoroplastic 46 can be used on corrosion-resistant ball valves. Its molding temperature is 320-350 °C, molding pressure is 3-30 megapascals, and shaping insulation temperature is 120-150 °C.

Shenzhen EMAR Precision Technology is dedicated to high-precision CNC Machining, with processing materials mainly including aluminum alloy, steel parts, copper alloy, POM, Peek, and PTFE precision machining. The product application fields include optics, intelligent robots, optoelectronics, automotive, communication, security, surveying and other fields.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque