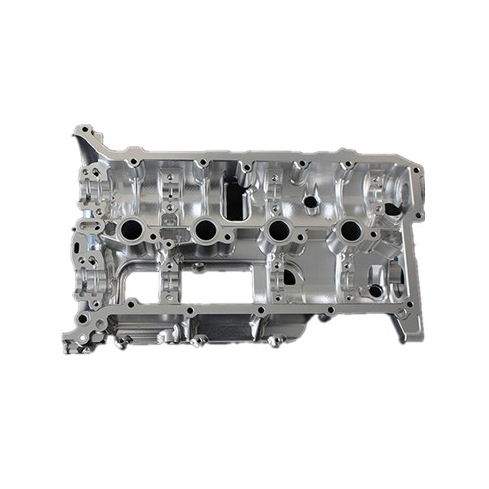

Accurationem machinae crucial est in partes machinae. Here are some commonly used methods and techniques to ensure machining accuracy: 1. Choose appropriate machining equipment and tools: Choosing high-precision and high stability machining equipment and tools is the foundation for ensuring machining accuracy. Exemplo, instrumenta CNC machinae et instrumenta velocitatis cutationis maxima machinae accuracionem et efficabilitatem possunt attingere. Control machining parameters: By controlling machining parameters such as cutting speed, feed rate, cutting depth, etc., machining accuracy can be ensured. Reasonable processing parameter settings can reduce the impact of cutting force, thermal deformation, and vibration on machining accuracy. 3. Using fixtures and positioning devices: Fixtures and positioning devices can ensure the stability and positioning accuracy of parts during the machining process. Proper selection and use of fixtures can reduce deformation and displacement of workpieces and improve machining accuracy. 4. Compensation and correction of errors: During the machining process, there may be errors caused by factors such as machine tool errors, tool wear, and thermal deformation. Impectus hoc errorum in precision machinae per errores compensationem et corrigentiam technicam reddere potest. Exemplo, utilis instrumenti functionem compensationis, tecnologiam deformationis compensationis thermal, etc. 5. Optimizatio procedentibus et controlo procedentibus: Optimizantes technologiam processoris et controlum procedentis accuracionem machinarum securi potest. Exemplo, arranging the processing sequence reasonably, using appropriate coolant, and controlling the ambient temperature can reduce deformation and errors during the processing. 6. Inspectio qualitatis stricto et controlo: Inspectio qualitatis stricto et controlo durante procedura machinaturae est modo importante ad accuracionem machinaturae. In regulari inspectione magnitudinis, formas, et superficie qualitatem opus, problemas in processione potest detect et addressere temporale, assecurantur accuractia processionis conforme ad requiras. 7. Scientiae operationis et experientia: Scientiae et experientia operatorum est etiam crucial in accuracione machinarum. Operatores need to be familiar with knowledge of machine operation, machining processes, and quality control, and be able to operate the machine correctly, adjust machining parameters, and handle problems during machining.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque