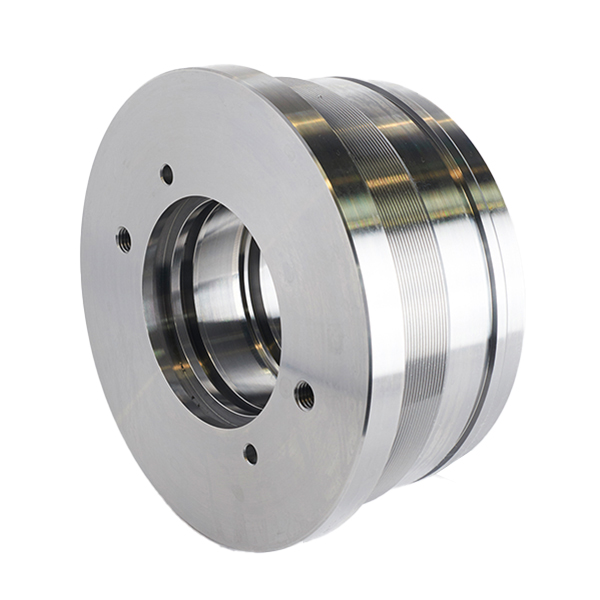

A large CNC Machining center is an efficient and high-precision CNC machine tool, which has multiple workbenches and automatic tool changing devices, and can complete the machining of various complex workpieces. Large CNC machining centers are usually equipped with good CNC systems and various sensors, which can achieve high-precision and high-efficiency machining, and are widely used in aviation, automotive, mold and other fields. The advantages of the  large CNC machining center include high precision: The large CNC machining center adopts good CNC systems and servo technology, which can achieve high-precision machining and meet the production needs of high precision and high quality. High efficiency: Large CNC machining centers have multiple workbenches and automatic tool changing devices, which can achieve fast and efficient machining and improve production efficiency. Flexibility: Large CNC machining centers can process a variety of complex workpieces with high flexibility, adapting to different fields and production needs. Automation: Large CNC machining centers are equipped with devices such as automatic feeding, automatic tool changing, and automatic measurement, which can achieve automation of the production process and reduce the labor intensity of workers.

large CNC machining center include high precision: The large CNC machining center adopts good CNC systems and servo technology, which can achieve high-precision machining and meet the production needs of high precision and high quality. High efficiency: Large CNC machining centers have multiple workbenches and automatic tool changing devices, which can achieve fast and efficient machining and improve production efficiency. Flexibility: Large CNC machining centers can process a variety of complex workpieces with high flexibility, adapting to different fields and production needs. Automation: Large CNC machining centers are equipped with devices such as automatic feeding, automatic tool changing, and automatic measurement, which can achieve automation of the production process and reduce the labor intensity of workers.

Salve! Welcome to the EMAR company website!

Latin

Latin » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque