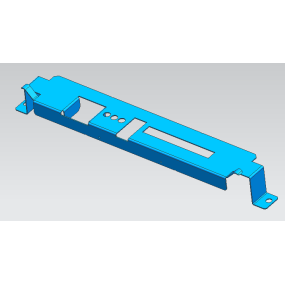

In manu fabricationis fabricationis fermentorum metalorum saepe est phenomenum fermenti metalorum, quod inducat ad inabilitatem lineae fabricationis producere et influent normam manum fabricationis fabricationis fermenti. Stamping mors cracking is a very common phenomeno. Usually, stamping dies only crack a small gap, but in severe cases, stamping dies may split into several pieces, which may affect the quality of the die. There are many reasons for mold cracking:

1,Selection of Press Machine

To improve the service life of Metal Stamping molds, it is necessary to select a suitable press machine. In general open press machines, the uniform regrinding life is 10000-30000 times, while on new precision press machines, the regrinding life of stamping dies can reach 60000-120000 times. Especially for small or no gaps stamping dies, hard alloy stamping dies, and fine stamping dies, it is necessary to choose a press machine with high precision and good rigidity. Otherwise, it will reduce the lifespan of the die, and in severe cases, it may also damage the die.

2,Reasons for mold design

In general, if the stamping die is designed with an unreasonable structure, insufficient strength, too close cutting edge distance, insufficient number of template blocks or no cushion pads, then the die faces a great risk of bursting. Mold design primarily includes the following points:

1

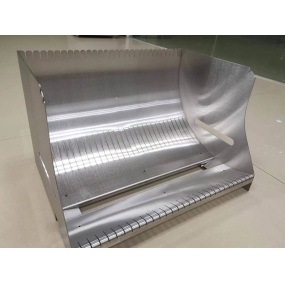

2. Precisio perducentis mechanismi: Precisio et fidelis guidance potest reddere vestimenta moli, preventere occurrentiam convex et concave morientiam morientiam, et optime adequat ad utilizacionem mortuum vacuum et parvulum punching interiorum, moribus compositis, et moribus pluribus station is progressivis. In addition, to improve the lifespan of the mold, it is necessary to select the correct guiding method and the accuracy of the guiding mechanism based on the nature of the processing technology and the precision of the mold parts.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque