Instrumentum pulchritudinis sunt instrumenta fundamental a fabricationis et processionis. Processum multorum molarum finium est adequate chaotica, et fluctum est lignum fundamentalissimum et praesentiam quam praecepit fitters.

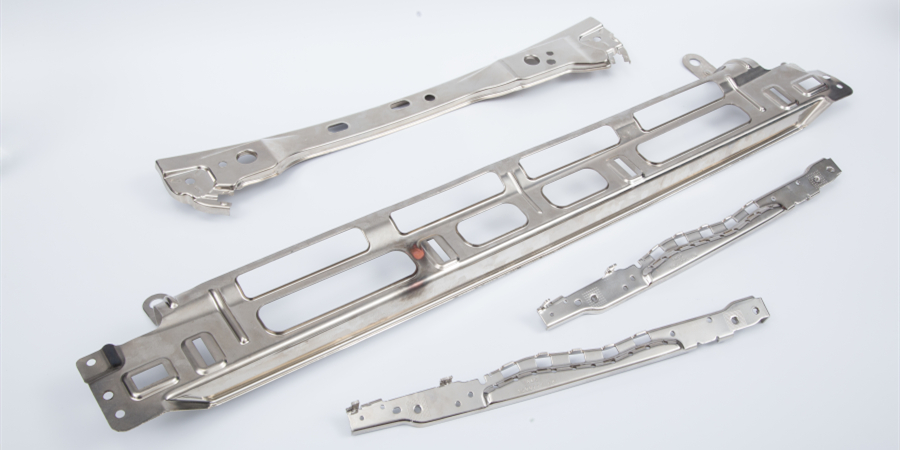

In processione mollium metallorum, requirement ad fluctum precision altissimus est. Conductione precision fluctus bene potest auxiliare meliorem qualitatem mollium et prodere meliorem partem pulchritudinis metallorum qualitatem. Precisionem constituere oportet accuracionem markorum, punctionum et fluctum certare.

1. Control of bottom hole accuracy

First, control the accuracy of line drawing. Examinate acutem pinum altissimi per trahendum linearum thinarum et profundum in una parte.

Then, control the precision of the Metal Stamping mold processing punch hole. In exemplo puncti, movere exemplum secundum centrum crucis marcata grova. Quando sentitus depression is in summo exempli est, indicat exemplum est in medio crucis. In hoc tempore, necesse est exemplum verticem esse, et operator facile parabolam ante punctionem accipiat. Post fluctum oculorum, necesse est verificare si orientatio accusa est. Si non satis accusa, necesse est solum parametros legire et objecto fluctus oculorum.

Finally, control the precision of drilling. Primus, use a drill bit to drill a shallow hole in the symbol direction of the metal stamping mold, measure the drilling direction and quality to see if it is qualified. If it is not qualified, adjust it repetitively until it meets the requirements. Attention ad bits drill cum longissimis angulis sectionis, quæ facile potest causare centrum nuptiae nimis altum. In hoc casu, recommenditur ut elegere bits drillus cum quasi nulla angulis sectionis maxime possibilis, dum satisficere praecepta drillum.

2. Control of drilling accuracy

Superiora superiora superiora foveae accuracionis in mollis est fundare foveae expansion is et multo importantium est eligere rationales mensuras ut controlare accuracionem foveae expansionis.

First, it is necessary to reduce the size of the drilling bit, enhance its active centering effect, and continuously reduce the drilling accuracy and cutting force; Secundo, adjust urendam ad fluctum, ut trillis graduam accedet ad portum inferiorem, et faciat modicum adjustationes ad perfectam delendum foram inferiorem de ore drillis. Finally, turn the drilling machine switch to perform mold drilling processing.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque