Procedentes partes fertilissimas fertilissimas fertilissimas, velocitatem, accuractem et precisionem debemus attingere. Sed, poterimus difficiles in processione. Infra, editor narrabit tibi de difficilis in processione partibus fertilissimis fertilissimis precisiis.

Due its high-quality edibility, formability, suitability, and strong ductility over a wide temperature range, it is widely used in industries such as heavy industry, light industry, daily necessities, and building decoration.

Stella Alloy cum continentia chromium maior quam 12% aut continentia nickelae maior quam 8% vocatur steela stainless.

Bu çeliğin atmosferde ya da corrosiv ortamlarında corrosiyon rezistenci derecesi vardır ve yüksek temperaturlarda yüksek güç sahiptir (>450 °C). Stella cum continentia chromium 16% ad 18% advocatur acidus steel resistentis aut acid is steel stainless resistentis, commonly known as stainless steel.

Pro superioribus steel is stainless, amplius in industriis sectoribus, quales aviatio, aerospace, chemical, petroleum, aedificationem, cibum et vitam cotidiae utilitur.

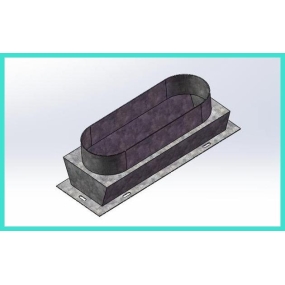

In protractione steela inmaculata sequentibus difficultatibus incipientur:

Sever work hardening: Stainless steel has high plasticity, distortion of properties during plastic deformation, and a large strengthening coefficient; In addition, austenita non est satis stabila, et aliud austenita potest transformare in martensitem sub concussione stress is; In addition, composite impurities are easily decomposed and dispersed under the action of cutting heat, resulting in a hardened layer during the cutting process. The work hardening phenomenon caused by the previous feeding or previous process seriously affects the smooth progress of subsequent processes.

High cutting force: Stainless steel undergoes significant plastic deformation during the cutting process, leading to an increase in cutting force. Stella stabilis habet laborem gravitatem et altam fortitudinem thermalem, quam plus incrementat resistentiam cutam et difficile facit fracturam et fracturam chips.

High cutting temperature: large plastic deformation during cutting, high friction with the tool, and high cutting heat; Multitudinem caloris concussionis in terra concussionis et interfacem instrumentorum chip contactorum concentratum est, resultant in pauperes conditiones dissipation is caloris.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque