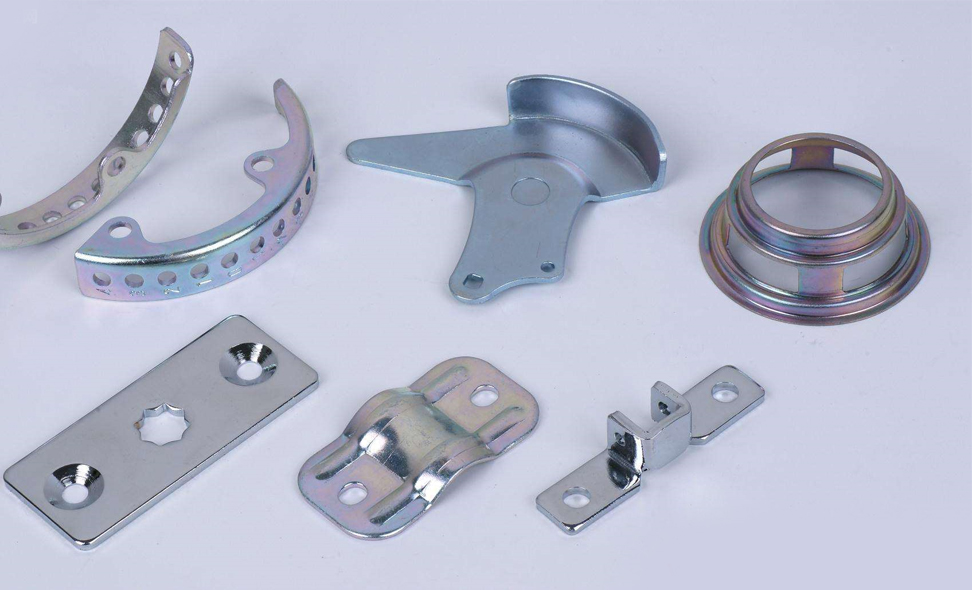

Precision stamping parts play an important role in industrial production. After years of development, China's precision stamping industry has gradually entered the formal stage and is constantly expanding in the world market. However, it has also led to higher development directions, but there are still many difficulties and problems, mainly manifested in the following aspects.

1. Poor manufacturing process

The research on the manufacturing process of precision stamping parts has accumulated a large amount of proprietary technology in the world, especially in century old factories, which have accumulated a large amount of proprietary technology and reached a high level of technological accumulation. However, China's proprietary technology accumulation in precision stamping is relatively small, and there is still a long way to go.

2. Short lifespan

The prominent issues affecting the service life of precision stamping are material and heat treatment quality. In hoc tempore, propter altam pretium fertilis importis et minimae productionis capacitatis, partibus precissimis plurima fertilis fertilis domicili utilizat. However, the poor quality of domestic steel materials, combined with unstable quality control and processes such as forging and heat treatment, results in significant differences in overall service life, generally one-third of that of foreign countries.

3. Poor analytical ability

The research on finite element numerical simulation technology and stress analysis simulation verification technology for precision stamping process in foreign countries has reached a high level, and has been applied to the design verification, design validation, and structural optimization of precision stamping parts. Quamquam universae universitates et scientiae in terra nostra scientiae fundamentale in hoc agro fecerunt, adhuc aliquid interim est in application hii technologiarum.

4. Low standardization

In order to improve the overall capability of China's precision stamping industry and accelerate the development of industry standards, it is particularly important to formulate national or industry standards for precision stamping in China, taking into account the comprehensive world standards and the actual development of the industry in China.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque