Quae procedentia sunt pro fabricatione pelliculae metallorum? Precision Sheet Metal Processing editor to answer.

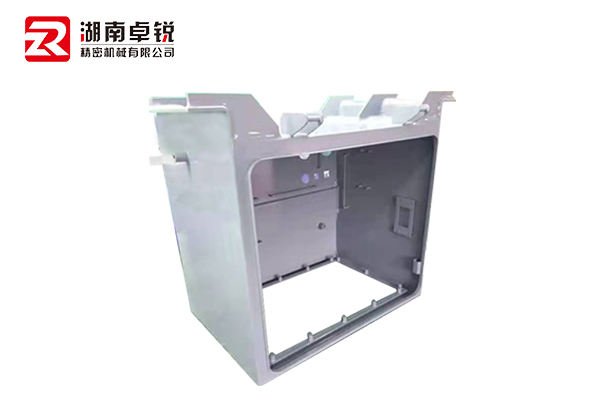

Sheet metalla shell processing refert to the process of processing metal sheets in shell parts of the desired shape. Sheet metalla shells are widely used in fields such as electronics, communication, automotive, and home appliances, and the corresponding processes and procedures can be selected according to the different needs and design requirements of the product. Sequentes sunt commune procedentibus ad processionem metalla folia:

1. Design confirmation and material selection: Based on customer needs and product design requirements, the shell design is carried out under the guidance of engineers, and suitable materials are selected. Materiae metallici generis includent plateas frigidas, plateas callidas, plateas sterilissimas, plateas aluminium alloy, etc.

2. Cutting: According to the design drawings, use cutting machines, CNC cutting machines and other equipment to cut the selected materials according to the required dimensions.

3. Bending and Forming: Use CNC bending machines, presses, and other equipment to bend and form the cut sheet metal to achieve the shape required by product design.

4. Welding: The bent sheet metal is connected through welding processes. Common welding methods include tungsten inert gas welding, pulse sheet metal welding, etc. Processo fermenti necesse attention ad controllum temperaturam fermenti et secundum qualitatem apparentiae post fermentum.

5. Gravitatio et pulcherrima: Polonia et pulcherrima pulcherrima ut meliorem faciem suam qualitatem et splendorem.

6. Surface treatment: According to the requirements of the product, the external shell is treated, such as electroplating, spraying, anodizing etc., to increase the corrosion resistance and aesthetics of the shell.

7. Assembly: Assemble the processed shell with other related components, such as installing switches, screws, connecting wires, etc., to form a complete product.

8. Testamentum et qualitatem control: Utrum instrumenta mensurae, instrumenta mensurae coordinata, et instrumenta inspectionis apparentibus et apparentibus, precision et qualitate processionis shell testantur et controllantur.

9. Packaging and delivery: Packaging the processed shell and delivering it according to customer requirements to ensure safe transportation of the product.

The above are the general processes for sheet metal shell processing, each of which requires specialized equipment and technology, and may also require other special treatments and processes according to product requirements during the actual processing. Sheet metal processing is a highly comprehensive process that requires engineers and technicians to have rich experience and professional knowledge to ensure product quality and accuracy.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque