The surface quality of automotive parts can intuitively reflect the micro and geometric errors on the surface of the parts. Of course, surface roughness is also an important indicator of the reaction, which is an important basis for inspecting the surface quality of the parts. The rationality of its selection directly affects the later product quality and service life, including production management. The methods for selecting the surface roughness of mechanical parts mainly include calculation, experimental, and analogy methods.

In the design of mechanical parts, the analogy method is widely used. The characteristics of this method are simplicity, effectiveness, and speed. The application of analogy method requires sufficient reference materials. Various mechanical design manuals now provide comprehensive information and literature. What is more important is the surface roughness that is suitable for the tolerance level. In general, the smaller the size tolerance requirement of mechanical parts, the smaller the surface roughness value of mechanical parts. However, there is no fixed functional relationship between them. For example, some handles on machine equipment and decorative parts on equipment have very high surface surface requirements in equipment sed minima minima necessaria. In general, there is a certain correspondence between the tolerance level and the surface roughness value of mechanical parts with dimensional tolerance requirements.

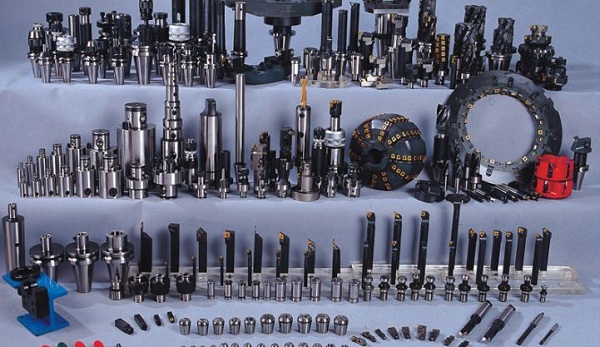

At present, the mechanical processing industry has put forward higher requirements for the improvement of technology and the use of cutting tools. It requires not only long service life, but also requires low pollution during cutting. Follow EMAR Precision Technology to take a look at the high requirements for cutting tools, high service life, and low pollution in mechanical processing.

Praecepta ad extinguendum instrumentorum in machinis CNC manifestantur in sequentibus aspectis:

1. With the development of technology, the mechanical processing industry has increasingly high requirements for the surface properties of materials, especially in recent years with the rise of various precipitation technologies, which have made breakthroughs in the research and application of surface engineering technology. These technologies not only meet the requirements of mechanical properties, but also demonstrate their capabilities in the fields of functional materials related to electromagnetic, optical electronics, thermal, optical, superconducting, and biological surfaces;

2. Surface engineering not only allows low-cost metal materials to have greater advantages in terms of performance and aesthetics, but has also become an important means for various new coatings and thin film materials with great potential for application;

3. The diversity of cutting tools and the characteristics of their usage determine the difference in choosing tool coatings. Turning is different from drilling, and milling cutters should consider their intermittent impact characteristics. The early development of coatings focused on wear resistance and improved hardness as the main indicator. During processing, constant friction between the tool and the workpiece will generate a large amount of heat energy. In order to avoid tool overheating and deformation affecting machining accuracy and extending its service life, cutting fluid is usually used;

4. Changes in the level of mechanical processing industry have led to the almost use of dry cutting in tool cutting. When cutting fluid is not completely eliminated, it is recommended to contain only rust inhibitors and no organic matter, which can greatly reduce the cost of recycling;

5. To solve some of the problems caused by reducing and eliminating cutting fluid, the tool coating should not only give the tool a longer service life, but also have self-lubricating function;

6. The emergence of diamond coatings has shown significant advantages in the mechanical processing of certain materials. However, recent studies have shown that diamond-like coatings with SP2 structure can also achieve a hardness of 20 to 40 GPa;

7. There is no problem with the catalytic effect of black metal, its friction coefficient is very low and it has good moisture resistance. It can be cut with coolant or dry cutting, and its service life is doubled compared to non coated knives. There is no problem with processing steel materials, so it has aroused great interest from coating and tool manufacturers. Over time, these new diamond-like coatings will be widely used in the cutting field.

The above is a brief explanation of the requirements for cutting tools in mechanical processing. Shenzhen EMAR Precision Technology Co., Ltd. focuses on customized processing and mass production of high-precision CNC parts. With more than 20 years of precision machining experience, EMAR is more confident in processing aviation parts, automotive parts, medical and communication parts. The company has passed ISO9001, ISO14001, and IATF16949 quality management certifications and strictly implements them, making it a trusted CNC Machining service provider for you.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque