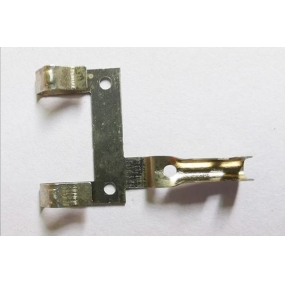

In lapidibus metallis processionis in Shenyang, factores that affect rebound include:

(1) The influence of material mechanical properties. Generally speaking, the higher the yield stress of the material, the greater the rebound.

(2) The influence of deformation degree and curvature radius.

(3) The influence of convoluted viewpoints. Quantum maior est perspectus tortuus, maior est terra deformation is, ita et maior est rebound.

(4) The impact of twists and turns. Lingua libera maior est quam mola bendere, et latitudinem et densitatem metallorum impleverunt super reboundum.

In general, there are many factors that affect rebound. A result of the impact of rebound, the bent edge cannot be tightly attached to the working part of the mold, but the corner edge is stretched out, resulting in a slight increase in the bending point. Therefore, the bending point of the sheet metal on the mold will not be the same as the working point of the mold, but slightly larger than the working point of the mold.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque