Shenyang Sheet Metal Processing emphasis est quod produkti habent altos standardes in terms of specifications, performance and other aspects, so strict requirements are placed on the sheet metal processing procedures. The typical sheet metal processing steps include cutting, bending, stretching, laser cutting, etc., and the final step is to complete the cutting process to achieve material separation.

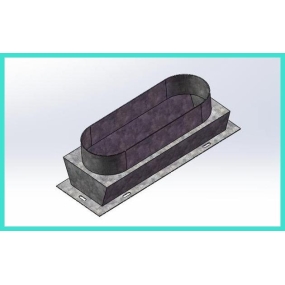

In processo depositionis materiae, post determinationem molarum superioris et inferioris, metallus folium statim fixus est in eis, et mollus superioris fertur ad perfectum stampionem. Sub pressionem molae superioris, metallus folium separatur ut possideret contour, formam et dimensiones design. Con meliorem technologicam machinarum punctionis CNC, partes cadentes in magna scala saepe habent characteristicas distinctas:

Primo parte separationis habet minores ardores et aestheticam apparentiam streamlinizatam;

Secundum causam est quod lapides metallis processae partes a secessione habent minores dimensiones, sic tempus necessarius unius produktus formationis minus est, faciens eos adequatum pro productione massae;

Tres, operatio material dropping on the CNC punching platform is simple and easy, and the operators don't need to have more professional and advanced skills or knowledge;

Quartus est quod CNC punching machines conditiones automaticas operantibus utilizat ad consummationem materiae, quae multo meliora potest utilizationem materiae in productione magna scala, ut costum superiorem efficientem faciat.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque