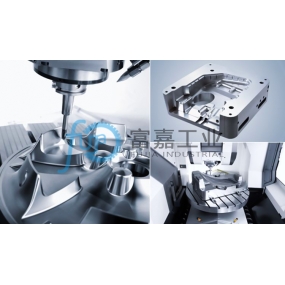

Precision Sheet Metal Processing is a high-precision mechanical processing method that requires consideration of many factors to improve processing quality and efficiency. Hic sunt modi referentiae:

1. Equatoria et seleccio instrumentorum adequa: Valde est ut elegere instrumenta et instrumenta quae sunt adequa ad processionem necessitatibus.

2. Proficient process technology: Processing technology has a significant impact on processing quality and efficiency. Laboratoribus bonum artificium et experientiam habere opus est ut alta qualitate processatio in eadem tempore consummaretur.

3. Fluxus procedentis optimizatus: Optimizantes fluxum procedentis, optimizantes effectivitatem processationis meliora potest. Cum fluxum procedentis formulatum fuerit, consideratio per singulos gradus tempore et resursu utilizatione debet, et optimizationis modis ad breviandum tempus processionis et accuracionem melior esse.

4. Reasonable fixture design: Fixtures play a role in fixing workpieces in precision sheet metal processing. Design fixturae rationale potest improvine processionem efficabilitatem et precitatem.

5. Control forte qualitatis: Implementation strict quality control measures can ensure the production of high-quality products. Exalta precision measuring instruments should be used for real-time monitoring during the processing, and process parameters should be adjusted in a timely manner to ensure the accuracy of the product.

6. Improve equipment maintenance level: regular maintenance and upkeep of equipment, timely inspection and replacement of vulnerable parts can maintain the normal working condition of the equipment. Hoc auxiliat evadere downtime causam ex equipationibus defectibus et productivitatem et qualitatem melior.

7. Automated production: Introducing automated equipment and systems can improve the efficiency and consistency of precision sheet metal processing. Automatica errores manus operationis reddere potest, velocitatem productionis et accuractem meliora facit.

8. Strengthen employ training and skills enhancement: Training employees on operational skills and processing knowledge, improving their professional quality and work level, is crucial for improving processing quality and efficiency.

9. Continuous optimization and improvement: In actual production, timely summarize and analyze problems and deficiencies in processing, and take measures to improve. Continuous optimization and improvement are key factors in improving processing quality and efficiency.

10. Productio securitatis: Strengthen safety awareness, strictly implement safety operation procedures, ensure the personal safety of employees and the normal operation of equipment, and avoid the impact of accidents on production.

In breve, qualitatem et efficabilitatem processionis metallorum precisii ex multiplibus factoribus dependant. Through appropriate equipment and tool selection, proficient process technology, optimized process flow, reasonable fixture design, strict quality control, equipment maintenance, automated production, employee training and skill improvement, continuous optimization and improvement, and safety production efforts, the quality and efficiency of precision sheet metal processing can be improved, thereby enhancing the competitiveness of enterprises.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque