Procedentia mechanica in factoribus stampionis optime descripta sunt:

1. Potentia tolerantiae

In processione mecanica, opus est ad specificationes et necessitates non signatum tolerantium formae. Errorem longitudinis inter 0,5mm esse, et zona tolerantium castationis simetricala esse. Equatoria fundamentala granditudinis vacuum castationis oportet respondere.

2. Requirements for Cutting Processing Parts

Praecepta partibus inspicuntur et testantur secundum proceduram. However, it should be noted that only after passing the inspection in the previous process can it be transferred to the next process. Impossibile est not are non licet in partes procedentes ardere. Cum placuit partes precision machinae, gravis est notare quod directo super terram positi non possint nec necessari sustinendam et sustinendam. Non oportet esse in terra maculata aut damno, qui potest effecti functionitatem, resultant in scratches, dentes, aut alios defectus, qui influent vitam aut apparentiam. Attention should be paid to the appearance requirements for processing, and there should be no compression or detachment. After the heat treatment process, there should be no oxide skin on the surface, especially on the cooperating surface after precision machining. The surface of dents should not have annealing conditions. Post processionem mecanicam non debet esse defectus, sicut pelle nigra aut pelles super superficiem virgae, quas industria processionis pulsere debet attention facere.

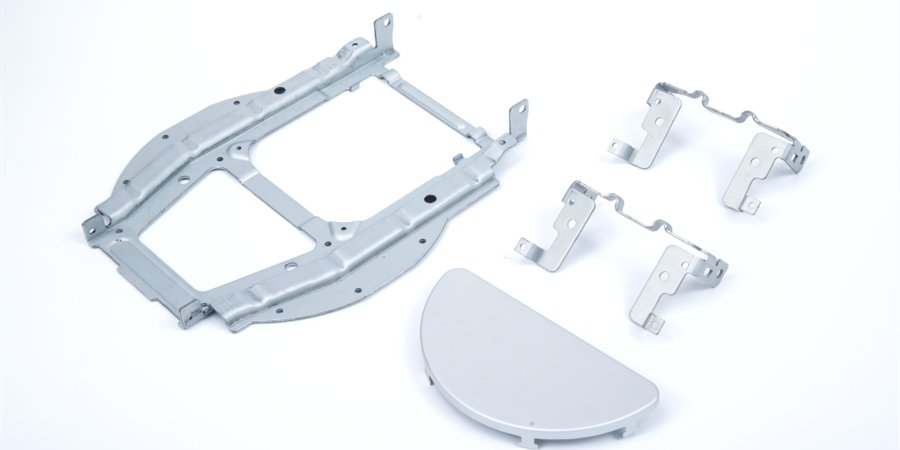

Mechanical processing for machine production includes the transportation and storage of raw materials, preparation for production, production of raw materials, processing and heat treatment of parts, assembly and debugging of products, painting and packaging, and other contents. Contents of the production process is very extensive. Modern enterprises use the principles and methods of systems engineering to organize and guide production, viewing the production process as a production system with inputs and outputs. It can make the management of enterprises more scientific, making them more adaptable and competitive.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque