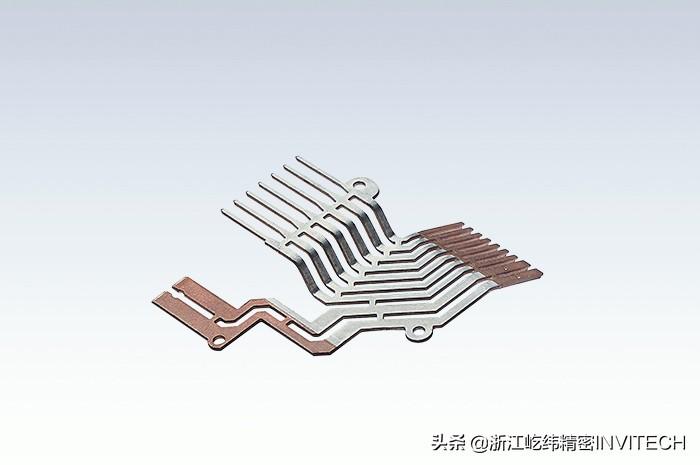

With the development of the electronics industry, the types and application scope of precision terminal stamping parts are gradually increasing, including PCB board wiring terminals, hardware precision terminal stamping, spring wiring terminals, etc. Zhejiang Yiwei Precision can design and produce various types of connector terminals, casings, precision stamping parts, and metal stretching parts. Welcome to customize with pictures and samples. Below, the editor will introduce the stamping parts of precision terminals.

Terminales precisionis coper quasi materiales conductive, cum conductivitate secundo tantum argenti metallici. Est optima electrica et physica, fortitudo alta, et non facile deformitur.

1. Touch architecture design - Precision terminals are selected with national/international universal plug-in, spring, rail and other interface methods. The transmission line can be close to conductive metal materials, and the touch is sturdy and not easy to loosen.

2. Production and Processing Specifications - Using precision machining CNC lathes, we strictly control the quality of precision terminal products, reduce the deviation of production and processing specifications of precision terminals to Z less than the control value, and carry out regular maintenance and upkeep of production and manufacturing molds to ensure the quality of every precision terminal produced.

3. Surface treatment - In terms of metal material conductivity, precision terminals are treated with electroplating tin technology, which can ensure excellent contact characteristics, reduce circuit resistance, and in addition, tin also has excellent anti-corrosion properties; Silver habet conductivitatem secundum tantum coperio, sed habet fidelitatem et bonas characteristices transmissionis signorum signorum, quae dimittere potest perditionem signorum datum in Z.

The above content is shared with everyone here. If you want to learn more about precision terminal stamping, please follow us, Zhejiang Yiwei Precision, a manufacturer of precision Metal Stamping, stretching molding, and precision injection molding.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque