Instrumentum machinae CNC dicitur CNC milling si non est bibliotheca instrumentorum et centrum machinarum si bibliotheca instrumentorum est. Utque CNC vocatur. CNC (Numerical Control Machine Tool) est abbreviation for Computer Numerical Control Machine Tool, which is an automated machine tool equipped with a program control system. Haec systema controlli potest logically procedere programmas cum codibus control aut aliis instruktionibus symbolic is et decodere ea ut actionem instrumentorum machinarum et machinam parterum actionem faciant.

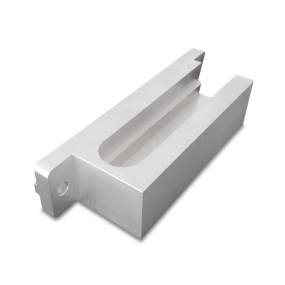

The so-called machining center refers to a CNC machine tool equipped with a tool library and automatic tool changing function, which performs multi process machining on the workpiece after one clamping. The machining center is a highly mechatronic product. After the workpiece is clamped, the CNC system can control the machine tool to automatically select and replace cutting tools according to different processes, automatically adjust the tool, automatically change the spindle speed, feed rate, etc. It can continuously complete various processes such as drilling, boring, milling, hinge, tapping, etc. Therefore, it significantly reduces the time for workpiece clamping, measurement, and machine tool adjustment auxiliary processes, and has good economic effects on parts with complex machining shapes, high precision requirements, and frequent variety replacement.

Centri Machining normale classificati sunt based on the relative position between the spindle and the worktable, and are divided into horizontal, vertical and universal machining centers. 1) Horizontal machining center: refers to a machining center set parallel to the spindle axis and worktable, mainly suitable for processing box type parts. 2) Vertical machining center: refers to a machining center set perpendicular to the spindle axis and worktable, mainly suitable for processing complex parts such as plates, discs, molds and small shells. 3) Universal machining center (also known as multi axis linkage machining center): refers to a machining center that can control the linkage change between the machining spindle axis and the worktable rotation axis to complete complex spatial surface machining. Suitable for machining workpieces such as impeller rotors, molds, and cutting tools with complex spatial surfaces. Below are the top ten machining centers in the world, and the data in this article is for reference only and does not serve as a single ranking basis.

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC Machining parts, metal stamping parts, and sheet metal processing.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole