The article brought to us by the Shenyang Sheet Metal Processing editor is actually an introduction to sheet metal processing. The most important thing they want to introduce to us is what a standardized process flow in sheet metal processing looks like, so that we can have a deeper understanding of this process specification. Quid sunt gradus metallis processentis quam calciamenta Shenyang fert te intellegere?

First of all, let me introduce to you the sheet metal parts in sheet metal processing. This actually refers to thin metal parts. Simply put, thin metal parts refer to parts that can undergo stamping, bending, stretching and other techniques for further processing, and the primary functional features will not be seriously lost in this step. Facilitate dicitur quia densitate partee in toto graduum processionis inmutata est usque ad finem processionis. In fact, to be honest, according to the current series of processes steps, for any sheet metal part, the reason why sheet metal processing is called processing is that all sheet metal has a certain processing step, which is actually what we call the process flow.

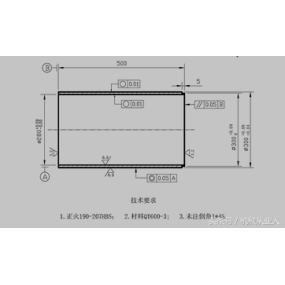

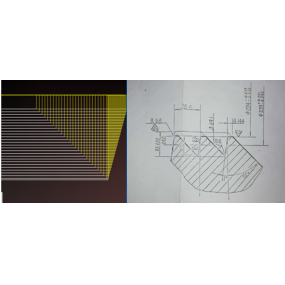

In simple terms, sheet metal processing can also be referred to as metal sheet metal processing. Detailed examples of its use in daily life mainly include: using sheet metal to make some commonly used tools in daily life, such as chimneys, iron drums, oil tanks, and other detailed objects. The first steps of sheet metal processing technology are cutting, riveting, bending edges, welding, bending and forming, etc. However, the detailed process flow of sheets metal parts varies depending on their structure. What the editor will introduce to us below is actually the most basic process flow in sheet metal processing.

Habitatique mensae mensae mensae mensae sunt: prima est mensae in mensis mensae mensae. Secunda mensis est creare mensuram secundum mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensae mensdevice and packaging for shipment. The above is the basic process introduction of the entire sheet metal processing.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque