Ass instrumentorum machinarum hic refert ad gradus libertatis instrumenti machinarum, et numerus axorum numerum graduum libertatis representat. Exemplo, tres axis usus ad motionem avionis arboris plus motionem instrumenti supra et desuper referunt, quattuor axis ad rotationem artis aut tabulae operantis in addition ad tres axes ante. In theory, plus asses sunt, plus gradus libertatis processionis instrumentorum machinarum, plus fortior functionis instrumenti machinarum. Sed hoc non significat, quod plus asses habere melior est. Multae rationes sunt pro hoc.

1. Besides looking at the number of axes, we need to consider the linkage

Whenever it comes to several axis machine tools, there is also a link between them. Ut prior mentionatus est, axis instrumenti machinae refert ad gradum libertatis instrumenti machinae durante machinae, dum connexio instrumenti machinae refert ad axis servo (exclusivo spindle) interpolationem simultane facire potest. Exemplo, quinque asses quinque ligamina refert ad motum coherentem quinque asserum motionis in machinationibus operantium. Si unus aut duo ex quinque axis simul non potest movere cum alteris axis, tunc instrumentum machinae vocatur "quinque asses quattuor linkae" aut "quinque asses tres linkae". In theoria numerus axorum decem, dozenas, aut etiam centum axorum attingere potest, sed connexio non necessarie potest tantum altum nivellum attingere. Hoc est etiam quinque asses quinque instrumenta ligaminis machinarum importantium resursum nacionalis consideratur. So when a multi axis machine tool comes out, there are always netizens who want to emphasize the link, because linkage can better demonstrate the performance of the machine tool in three dimensions.

2. In addition to degrees of freedom, accuracy and rigidity are also important

Machine tools refer to machines used for manufacturing machinery, with a wide variety and scope, playing a significant role in the modernization of the national economy. For different types of machining, the requirements for machine tools types and performance are also different. Therefore, although multi axis can bring higher machining freedom and functionality, many times the workpiece to be machined is not so complex, and instead requires higher precision and rigidity from the machine tool. At present, multi axis machine tools have obvious advantages in complex workpiece processing and efficiency, but there is no absolute advantage in accuracy. On the contrary, a due to the complex body design, the rigidity of the machine tool is slightly weaker. In breve, esse adequatus pro processione optimus est. Cum facientes diversis opera ad processendum, habentes plures axes machinae non necessarily melior est.

About the selection of five axis linkage machine tools

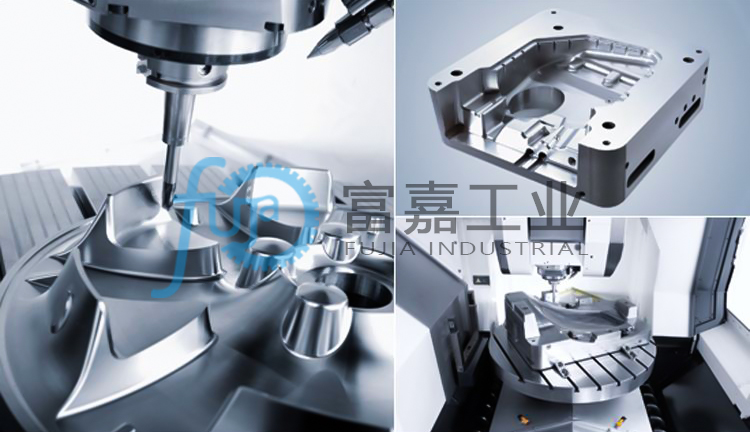

Although not all machining requires the use of five axis linkage machine tools, they do represent the high-end level of machine tools and are an effective means of solving complex machining problems such as impellers, blades, marine propellers, and heavy-duty generators. With the development of manufacturing industry, the processing requirements for machines are becoming increasingly high, and the consumer market for five axis linkage machine tools is also expanding. So what parameters can be considered when selecting a five axis linkage machine tool? Below, the editor will briefly introduce it.

Pro diversitatem parterum et factorum processorum, quasi velocitatem machinae, accuractem et robustotatem, quinque axis linkae machinae machinae specialisae est. Pro hoc, cum quinque instrumentum de ligamine machinae asses designare et elegere, primus gradus cum processione parti et trajectorio machinae typicae cogitare est, id est, ut considerare characteres motion is relativae inter instrumentum et partem, accuracionem/velocitatem/spatiom instrumentae motion, classificationem axis motionis instrumenti quinque asses ligaminis machinae, et inspectionem accuracionis.

In addition, in the design and selection of high-speed five axis linkage machine tools, the following basic principles must be followed. 1. Estne characteres motionis structurae instrumenti machinae conforme ad characteres motionis trajectoris instrumenti relative to the surface of the part? 2. Estne "accuractia motionis compositis" instrumenti machinae iuxta necessitatem trajectoris accuracii et velocitatis motionis? 3. Estne speculatio magnitudinis instrumenti machinae in spatio necessario propter trajectorium gestionis instrumentorum? Si non sunt problema supra, potuerit basically confirmare quinque asses linkae machinae conforme ad requirentes machinae.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque